Robotic Solutions: Determining the Right Option, and Safety Factors

At Precision Automation®, our robotic automation solutions do not adhere to a “one size fits all” type of manufacturing strategy. On the contrary- our experts understand that no two customers are exactly alike, and that each client requires robotic automation solutions designed specifically for their product, process, environment, and needs.

Precision Automation® provides our customers with multiple variations of robotic equipment options that can be optimized for specific production line operations, which may lead new customers to question which type of automation solution will best suit their operation. Explore the advantages that differentiate each robotic automation solution from the others and discover what option will work best for you:

Robotic Automation Solutions: Gantry Robots

Gantry robots (also known as linear or cartesian robots) are perhaps the most straightforward and easy to program robotic systems. Because these types of robotic arms are fixed to a rail, they offer a more linear range of motion than the alternatives. This means that they allow for easy movement across a horizontal plane, and operate across the X, Y, and Z axes. If this applies to you and your industry, then gantry solutions will provide you with a large operational area range and exacting precision where it concerns automated robotic positioning.

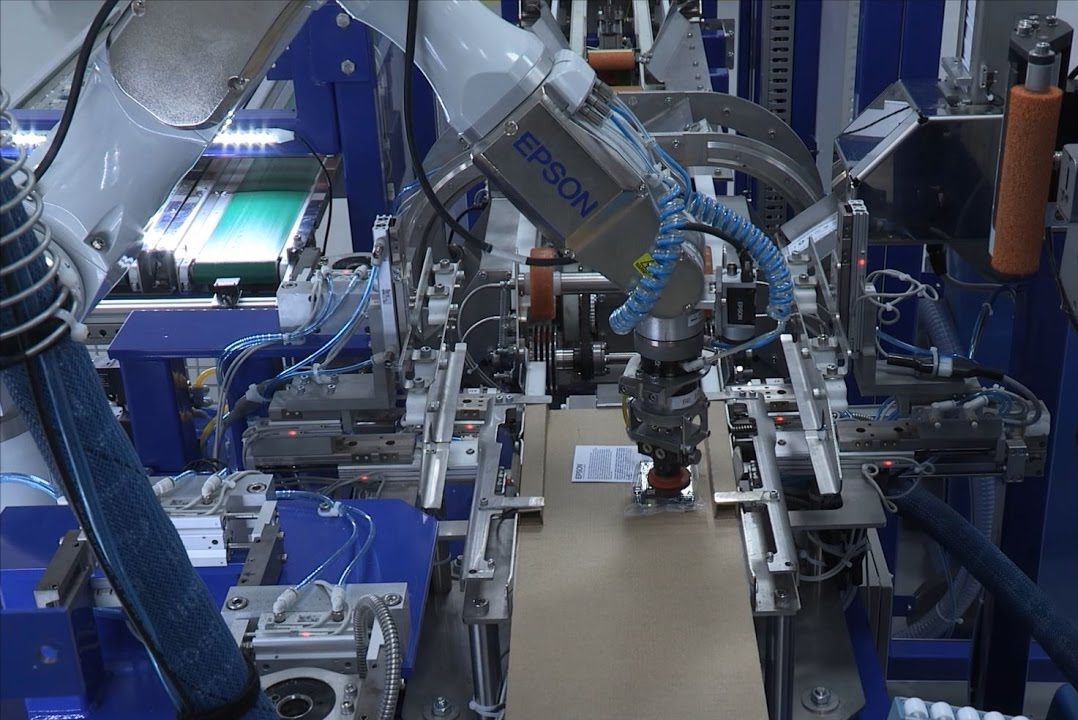

Robotic Automation Solutions: Articulated Arms

While gantry robots certainly present a number of advantages, what if a customer requires a more flexible range of motion? An articulated arm robot utilizes multiple axes (most often 4-6) to allow for more “human-like” ranges of motion. Each axis represents a joint, which allows for the automation of more complex processes, such as packaging or pick and place tasks. This increased motion range is ideal for production line automation as well as a variety of other manufacturing-related tasks. The versatility of an articulated arm provides a greater range of work than other models, which is why these robots are one of the most popular automation solutions among all of Precision ’s offerings.

Robotic Automation Solutions: SCARA Robots

Selective Compliance Articulated Robot Arm, or SCARA, robots can be a very useful alternative to gantry or articulated arm styles. These robotic systems can move about the X, Y, and Z axes- like gantry robots- but the difference is their circular work envelope, allowing a 360-degree rotational movement around the Z axis. In many instances, SCARA robotic systems can operate at faster speeds than an articulated arm, and their compact footprint requires minimal space for operation, which further elevates these pieces of equipment as ideal options for many assembly projects. While SCARA robots present many benefits to the end-user, it is important to note that these types of robotic automation solutions work best for small assemblies, which makes them ideal for projects with light payloads.

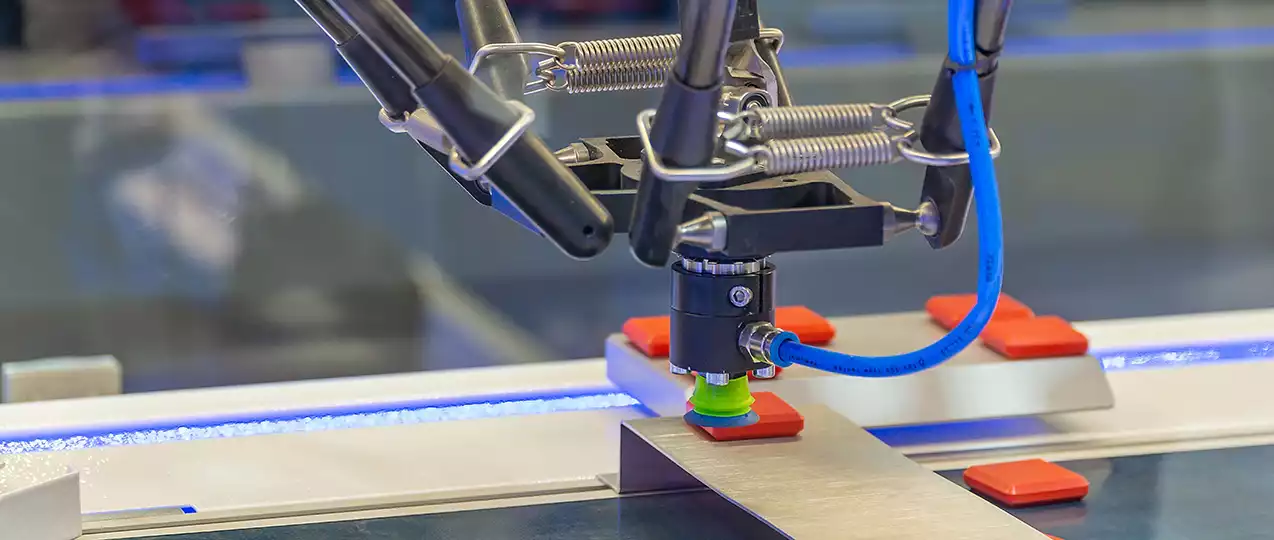

Robotic Automation Solutions: Delta/Parallel Link Robots

Another robotic system that employs the use of all three axes are delta robots, which are also known as parallel link robots due to the parallelogram design of their three or four arms (and commonly known as “spider robots” because of their appearance). These robotic systems are very fast, with their long arms performing the majority of the movements, and the motor located overhead- contained within the main console- controlling all actions. These delta robots are often seen in assembly lines throughout numerous industries, but are also ideal for pick and place applications, small parts transfers, or dispensing motions.

Robotic Automation Solutions: Collaborative Robots

As the most human-like in terms of range of motion, collaborative robots (or “cobots”) stretch the limits of what is able to be automated within our customers’ workspaces. Collaborative robots do not require the same amount of guarding as other robotic solutions, making them useful for automating processes that are more dangerous for humans to perform. These robotic systems are typically easy to program and their full range of motion is a great asset to the customers who require specific automation capabilities to perform repetitive actions instead of an employee doing so. By utilizing cobots, productions can run 24/7 and assist companies in meeting rigorous customer demands.

Enhanced Safety through Robotic Automation

Regardless of what type of robotic system is chosen, between differing advantages or disadvantages- any of them help to create a safer work environment. While it may be daunting to switch processes and adopt a new method of operation, the Precision Automation® team looks to demonstrate to potential customers that our integrated robotic automation solutions can improve workplace safety, in addition to increasing productivity.

Robotic Solutions Eliminate the Risks of Human Error

An investment in robotic automation solutions is one of the most effective ways to avoid the safety risks that result from human errors. While workplace safety has taken strides of improvement over the last few decades, no manually operated workplace is completely guarded against errors that could prove costly. Even with rigorous safety measures in place, manual labor becomes dangerous when employees face fatigue, which ultimately results in reduced focus, and the increased likelihood for a mistake that could damage products, or worse: injure a fellow employee. This recent article from Robotiq emphasized that point, and discusses how “robots can help reduce 35% of work days lost to injury.”

Robotic Solutions Reduce Long-Term Ergonomic Issues

In addition to presenting a solution for fatigue and related human error, Precision’s robotic solutions address the long-term safety risks associated with manual labor. In work environments that thoroughly train for safe workplace habits, with systems in place to reduce employee fatigue, companies still often face the hazard of ergonomic issues.

Any repetitive job that requires manual lifting and/or lowering of products and packages can run the risk of affecting the long-term physical health of employees. These issues may become costly to a workplace over the course of time, and can negatively impact workplace morale. Our robotic solutions address these concerns by literally taking the brunt of the weight off employees, and instead automating these transporting and packaging processes. Not only does this integration optimize workplace safety, it also allows employees to dedicate their time and expertise to more complex workplace concerns.

Training on Robotic Safety Processes

While the safety benefits of automated robotic systems are plenty, there are always additional ways to continuously increase workplace safety even after these solutions have been implemented. To minimize safety concerns associated with robotic automation, the engineering team at Precision Automation® is happy to provide basic training to the operators when introducing new equipment to your facilities. By ensuring applicable employees understand what to expect when working with new robotic technology, safety is prioritized at all times and harmful accidents can be avoided entirely!