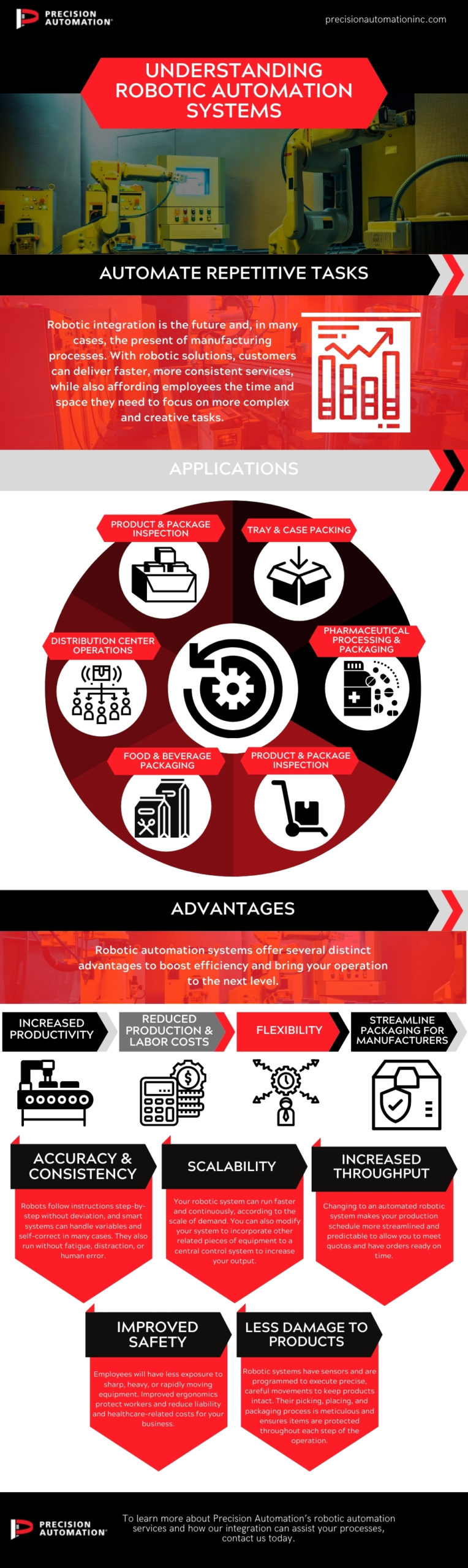

Different Types of Robots

To meet the varied needs of different tasks and industries, robotic systems come in many forms.

Here are a few common types of robots:

-

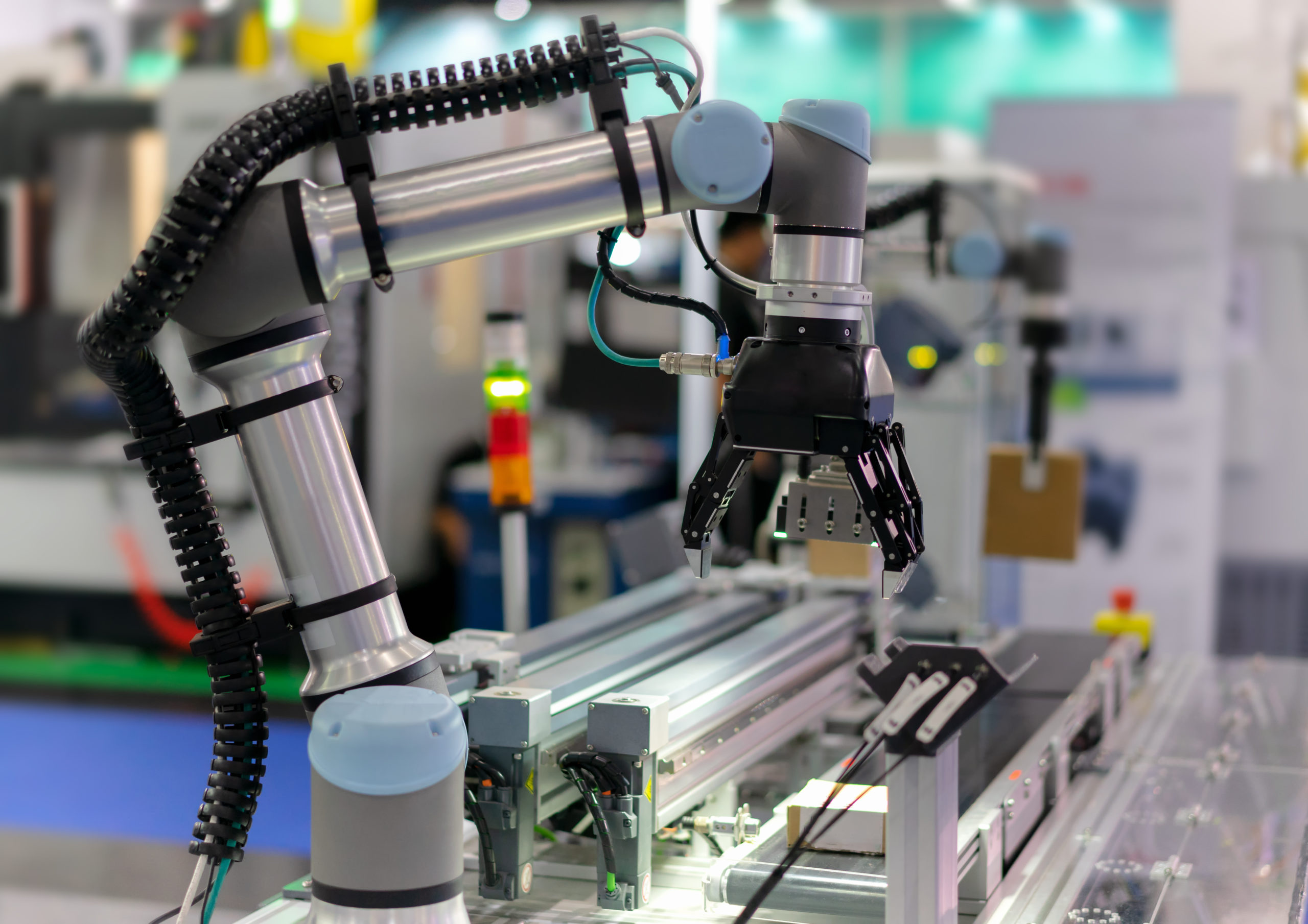

Articulated Arm: An articulated arm can be used for wrapping, boxing, and pick-and-place tasks that sort products into different categories. They can identify, grasp, and move goods around from a fixed position or conveyor belt.

-

Gantry: Gantry robots are like arms but are fixed to a rail. This allows for quick linear movement that can be used on a wide range of applications.

-

SCARA: Selective Compliance Articulated Robot Arm (SCARA) robots are used for small assembly systems. They can handle a wide variety of tasks because of their ability to move about the X, Y, and Z axes at high speeds.

-

Delta/Parallel Link: Delta robots, also known as “spider robots”, are more humanoid and have a bio-mimicking design. They have multiple arms connected to a single base, operate quickly, and are commonly used in pick-and-place systems.

-

Collaborative: Collaborative robots replicate human motions and do not require guarding. They are typically slower but operate within the same space as humans and are easy to program.

Contact the Automation Experts at Precision Automation® Today

Robotic systems are fast and consistent. They can streamline your facility’s packaging process, reduce the risk of human error, and help businesses manage costs. At Precision Automation®, we specialize in creating custom automation systems for industrial applications across multiple sectors. Our company is robot brand-agnostic so we work with a number of different manufacturers in order to develop the proper solution that fits your application needs. Contact us today to learn more.