How Can Custom Packaging System Integration Help My Business?

Custom packaging system integration has become a more prevalent business strategy for a wide range of customers. For many businesses, a single piece of machinery will not answer their operational needs, so they may require more custom integration for their unique packaging environment. Depending on the industry, custom packaging integration has the potential to exponentially increase profits and improve upon the quality of previous packaging strategies.

Precision Automation® is proud to be able to investigate production issues that our clients face, and aim for our solutions to optimize their packaging workflow operations. Learn more about the advantages of custom packaging system integration by reading further.

Increase Productivity with Packaging System Integration

One of the most obvious benefits of custom system integration is that these solutions allow for heightened levels of workplace productivity. By automating more steps in the packaging process, system integration enables the manual workforce to dedicate their time to the more pressing tasks of their business.

By reducing the amount of time spent on repetitive packaging processes, the overall productivity increases. Furthermore, because our packaging system integration solutions are customized, increased productivity is not achieved at the expense of quality packaging. In fact, with the latest examples in innovative technology, many of our customers achieve higher levels of packaging throughput, consistency, and quality than they were previously able to achieve manually.

Increase Packaging Flexibility with Packaging System Integration

By integrating more packaging systems, customers not only increase workplace productivity, they also increase the adaptability of their packaging processes. Whether their process needs to be adjusted to correct a printing error, or whether the system simply needs to be adjusted to account for new products being packaged, these technologies are inherently flexible. Whereas during manual packaging, changes can often only be made once the entire packaging team has been notified, customized solutions can be adjusted by a single operator in most cases.

Reduce Manual Labor and Waste with Packaging System Integration

In recent years, labor shortages have presented countless challenges for production facilities across many different industries. As a result, it is an advantageous strategy to invest in equipment that reduces the amount of manual labor required for repetitive tasks within a production or processing site.

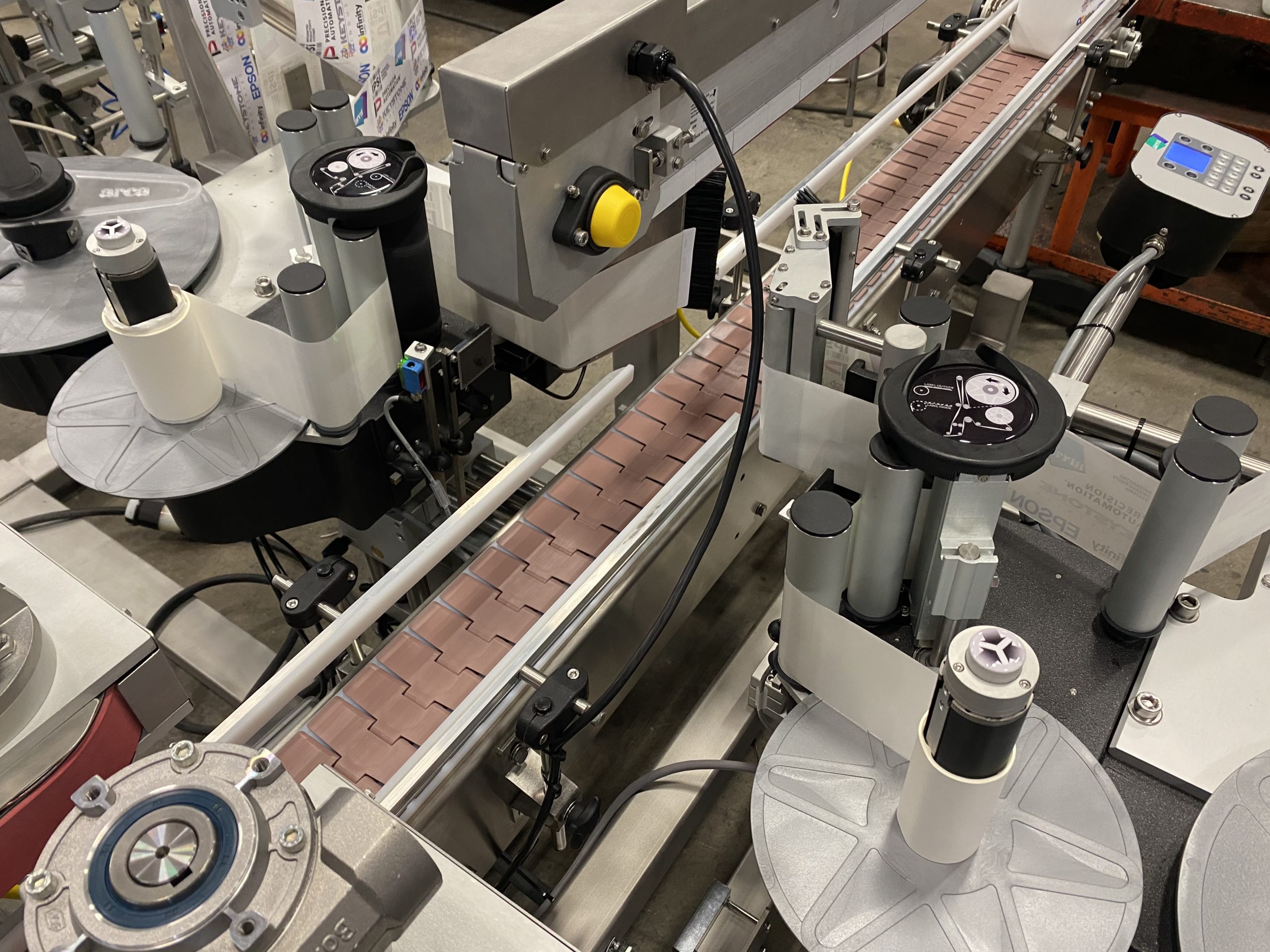

Packaging system integration accomplishes this by automating the aspects of the packaging process that do not inherently require personal attention from the manual workforce. Automatic case packing & sealing systems, checkweighing machines, print & apply labeling systems, and palletizers combine to show an example of this type of integration. Additionally, these pieces of technology work to optimize the packaging process by eliminating much of the risk for human error. As a result, custom packaging integration systems reduce overall facility waste as well.

Improve Customer Satisfaction with Packaging System Integration

Each of the advantages mentioned above serve to not only improve the working conditions of individual businesses, but also to ultimately increase the overall ability to achieve customer satisfaction. By improving packaging quality while simultaneously keeping costs low and improving ergonomics for their workforce, businesses are able to provide their customers with competitive prices for their products while still delivering a high quality of output.

If you have been looking for a way to maintain high quality standards and customer service, custom packaging system integration may be a useful strategy for you and your company. Contact us to talk to our sales engineering team about how we can assist your business today!