Laser Marking for a Variety of Applications

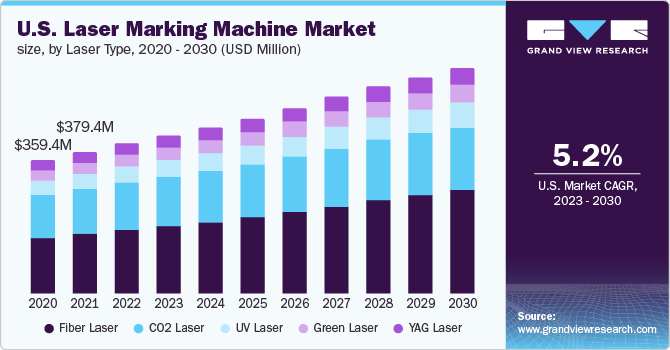

As end-users purchase more & more packaged goods, the manufacturers typically produce more consumables throughout the process. But laser marking solutions offer a permanent marking technology that saves material costs. In an increasingly automated world, the market for laser marking systems has grown substantially in the last decade. Studies are showing that the global laser demand will continue to increase even further into the remainder of the 2020s, per the chart below.

The question becomes: with such widespread demand for these marking machines, what are companies looking to use them for? In this blog, we will break down a number of different surface applications for utilizing laser technology to permanently mark text, dates, lot codes, barcodes, images, or a combination of any of the above.

Laser Marking Beverages

In the process of bottling and packaging beverages, laser marking the batch numbers and expiration dates on each bottle is crucial to both the manufacturers and the clients. It is important for the manufacturers (or distributors) to know and be able to track bottle count in each batch for accountability purposes. And for the end-user who is purchasing this bottle or case, having a clearly visible expiration date is vital for the health of the consumer.

In this short video example clip below, the bottles are conveyed at a rapid rate directly past the Fiber Laser Marker, which applies a numerical code in-line as the bottle is rotated.

Laser Marking Wooden Barrels

Before beverages even make it into a bottle, laser marking can also be applied effectively to the outside of wooden barrels that age wine or spirits (such as bourbon). By removing a microscopically thin sliver of the wooden surface by use of the CO2 Laser Marking System, a company could significantly boost its brand awareness with a unique logo on the barrel cap.

(For additional cooperage machinery services, visit the site of our sister company pāco manufacturing in southern Indiana.)

Laser Marking Plastic Planters

Examining a specific application, laser marking systems can be employed to etch information such as lot or batch codes onto the sides of plastic planter pots. This example goes to show that various types of plastic material are certainly appropriate to laser mark, and this unique case illustrates the possibility of a concave surface being marked.

This particular case can also apply to other types of plastic containers with a curved surface that need to be distinctively marked without the use of paper labels. And much like the system used for wooden barrels, this CO2 Laser Marking System that marks plastic has a life expectancy of approximately 40,000 marking hours.

UV Laser Marking on Plastic Bags

If plastic planters can be laser marked, then you guessed it: so can plastic bags. Unlike with the Fiber & CO2 systems, this application utilizes a UV form of laser marking to create a high-quality, permanent mark on the outside of plastic poly bags.

This example can be useful for QR codes, which can be small yet also require a clear mark, or else their usefulness is depleted. The markings produced by UV laser on plastic materials have a high contrast, which makes them instantly easier to read & identify for highspeed vision systems. And unlike the other types of laser markers, UV laser marking is a non-contact process which protects the quality of the product within the plastic bag.

Laser Marking Stainless Steel or Chrome

For those businesses that produce plumbing components or other stainless steel (or chrome) products, laser marking can be especially useful. Many of these types of products are oddly shaped due to their functionality, which makes identifying them difficult without considering an extra packaging process. Enter a laser marking process tailored for these characteristics.

By using a distinct system that holds these specialty parts in place during the laser marking process, it allows for 360-degree application of a part number or purpose-related markings. As with any of the other laser markings, the end result is permanent & easy to interpret with the naked eye.

Laser Marking Pallets

The final laser application we are exploring is marking directly onto pallets. To truly revolutionize your pallet handling logistics with a sustainable way to increase accountability, consider using a laser marker to apply a unique code to each pallet. Versatile to work with either wooden or plastic pallets, this laser marking technique enhances traceability and is sure to positively impact your pallet inventory organization.

These are just a handful of specific applications in which laser marking solutions can be utilized to assist your operation. But if you have a product or material that you would like to run some tests and see if laser marking would be an applicable, cost-saving option: contact us today.

Our team of sales engineers are eager to learn about your current product handling or labeling process to see if it is something that we can help streamline with this innovative machinery. Leave the costly consumables behind and look toward the future with accurate, precise, and permanent laser marking technology!