Can Automation Help Solve Supply Chain Problems?

Few industries have been spared from the extreme supply chain challenges that have arisen over the last few years. As a result, countless companies have been reviewing their respective strategies for handling these concerns, hoping to set themselves up for greater success in the event of continued and future challenges.

Utilize Manufacturing Automation Services to Offset Supply Chain Difficulties

As an organization that works with many customers from a wide range of diverse industries, Precision Automation® has made a concentrated effort to understand the areas in which our automation solutions can be used to solve bottlenecks and slow-downs for our clients. Explore the advantages of our manufacturing automation services, especially as it relates to supply chain management:

Efficiency with Manufacturing Automation Services

One of the most significant ways that manufacturing automation services can benefit customers is through helping to optimize facilities for maximum efficiency. Warehouse automation, in particular, can utilize employee labor to focus more on complex tasks while automated systems execute the repetitive, mundane tasks. By enabling a way to adapt workflows according to operational changes as supply and demand levels fluctuate, automation solutions work to keep companies running regardless of the industry’s climate.

Manufacturing Automation Services Support Your Workforce

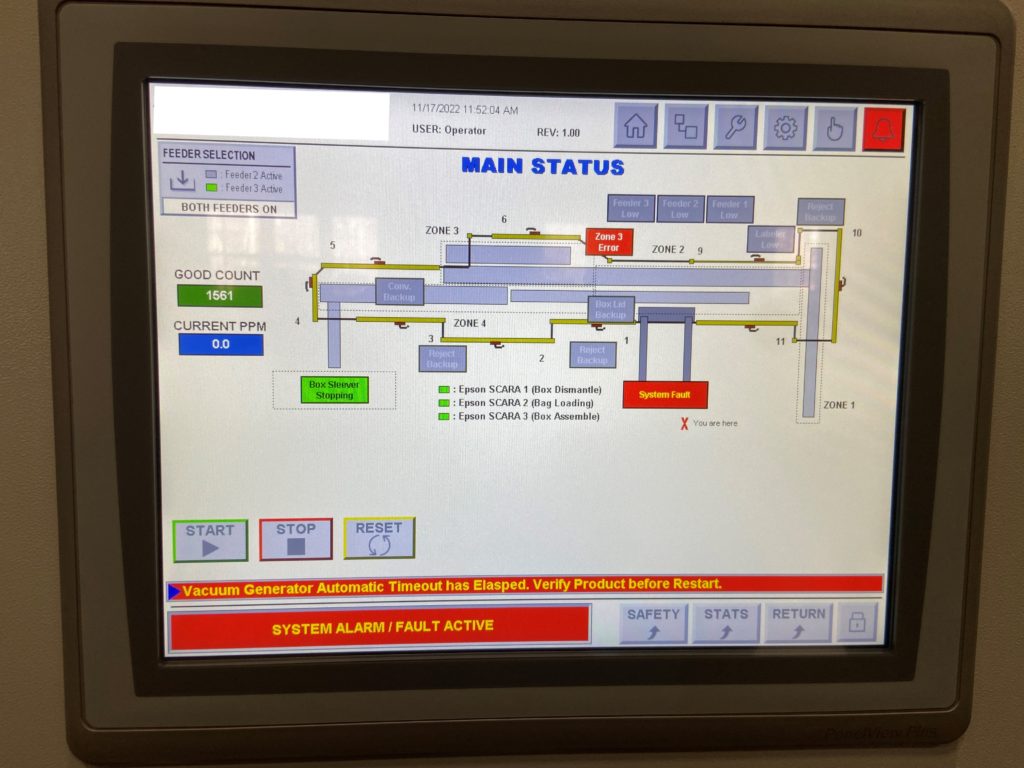

Supply of materials is not the only concern that faces manufacturers– a shortage of workers creates a multitude of issues as well. Manufacturing automation services address this problem by providing reliable, continuous productivity without requiring much hands-on attention from operators. By minimizing the mistakes potentially made through human error, and displaying accurate, on-demand data results through modern HMI (Human Machine Interface) technology, automated systems have proven to support businesses that face labor shortages.

Manufacturing Automation Services Provide Real-time Adjustments

The advancements in automation technology implemented during times of supply chain disruption showcase the ability to integrate software which can adapt to changes in real time. Our automation solutions also deliver data that provides complete visibility and the predictive capacity needed to deal with future disruptions. These examples of system integration can make a considerable impact on how managers and supervisors can track their facility’s production value.

Manufacturing Automation Services Produce Less Waste and Conserve Materials

While human error is inevitable where manual labor is concerned, automated solutions minimize human interaction, thereby lowering the risk of waste during production. By drastically reducing the likelihood of duplicate orders, incorrect data entry, and packaging the wrong products, automation systems yield more consistently accurate results. Integrating solutions that repeatedly carry out repetitive end-of-line processes makes it possible to conserve some hard-to-obtain materials that will be used properly for correct orders. As a result, the pressures of supply chain challenges are not fully realized and thus make production runs exponentially easier and more efficient.

Is your company facing issues as a result of the supply chain situation? Have you thought about automation integration before, but unsure about where to start, or how to correctly implement within your facility? Contact the Precision Automation® team to tell us about what is slowing you down, and examine how our automation solutions can make a difference on your bottom line today!