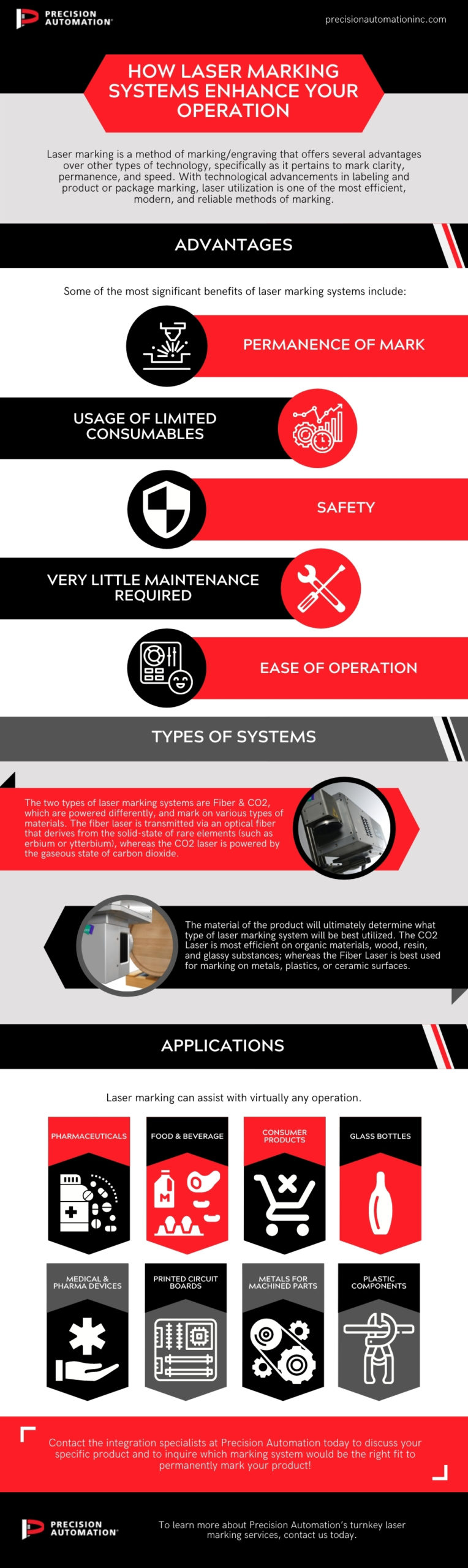

How Laser Marking Systems Enhance your Operation

Identifying Efficient Ways to Improve Production and Process Automation

Laser marking is a method of marking/engraving that offers several advantages over other types technology, specifically as it pertains to mark clarity, permanence, and speed. With technological advancements in labeling and product or package marking, laser utilization is one of the most efficient, modern, and reliable methods of marking. The most significant benefit of laser marking systems- aside from the permanence of the mark, which remains long after labels have fallen off- is the usage of limited consumables compared to labeling or printing. Laser marking systems are also very safe, require very little maintenance, and are easy to operate for most employees in the manufacturing industry.

The origins of laser technology can be traced all the way back to Albert Einstein who, in 1916, predicted the phenomenon of stimulated emission which is essential to all laser functionality. Throughout the next few decades, scientists would continue to explore this technology while Hollywood was depicting lasers fictionally in James Bond films and various futuristic movie scenes. Finally in the 1970s an artist named Tom Zarden purchased a prototype laser machine and changed the game. He made improvements on the method and used the laser to engrave wood, and by the end of the 1980s had sold more than a hundred machines.

Today, lasers marking systems are designed and implemented significantly more than even 5 or 10 years ago. But plenty of potential customers are still unaware of the benefits of such machines, or are simply too wary of what could go wrong with this powerful technology. To assuage these feelings, a 2-channel safety measure has been equipped for each system along with a manual reset. Furthermore, the engineering teams who design and integrate the laser marker with your process ensure that every degree of additional protection is instilled to ensure the utmost safety.

The term LASER is, in fact, an acronym for: Light Amplification by Stimulated Emission of Radiation. It all starts with the electromagnetic waves of light; as these wavelengths hit any object, the ones that are not absorbed by the object reflect color to the naked eye. Ordinary light (e.g. from a bulb) emits waves that spread apart in many directions, whereas light waves from a laser travel directly, in a straight line, all in the same color with almost no deviation.

The two most common types of laser sources also determine the two most customary types of laser marking systems: Fiber & CO2. The transmission source method of the fiber laser is an optical fiber that derives from the solid state of rare elements, such as erbium or ytterbium, whereas the CO2 laser is powered by the gaseous state of carbon dioxide.

‘So what does any of this have to do with packaging innovation?’

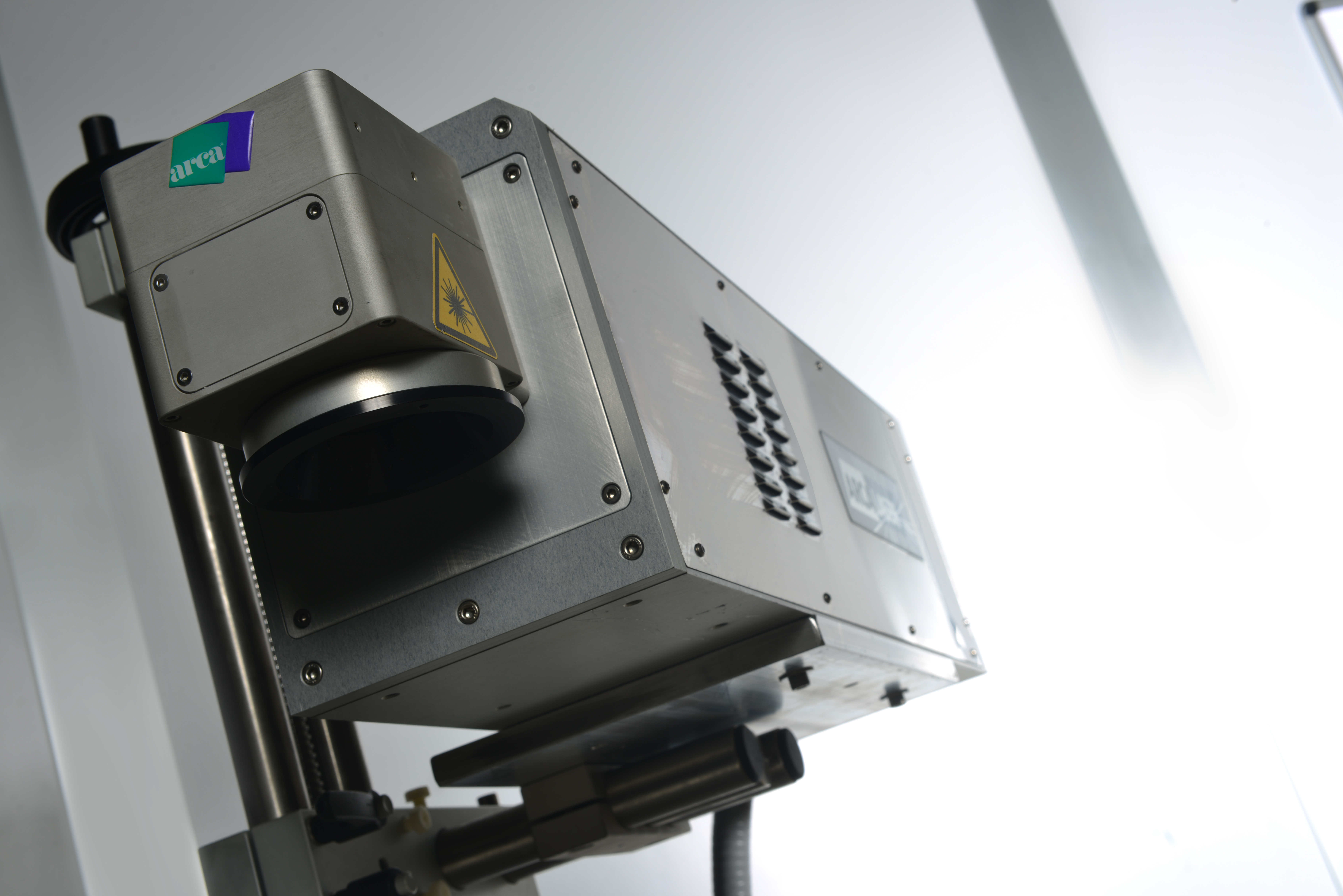

The line of Arca Laser Marking systems offers a multitude of uses, including marking directly on corrugated boxes. With the help of a specialty coating applied to cardboard packaging material, the Arca CO2 laser can mark content barcodes straight on to the box, eliminating the need for labels and ink.

Perhaps lasers for packaging are not of interest to you; instead you are looking to use laser marking systems for a more product-centric use, like imprinting a logo, serial number, line of text, or a lot code onto a particular item. The material of the product will ultimately determine what type of laser marking system will be best utilized. The CO2 Laser is most efficient on organic materials, wood, resin, and glassy substances; whereas the Fiber Laser is best used for marking on metals, plastics, or ceramic surfaces.

Regardless of the type of laser used, both marking systems are engineered to mark on the fly, and that is where Precision Automation comes in. Our experienced sales engineers integrate the proper conveying or material handling systems to work closely with the laser marking system and ensure proper processing of your specific product.

These systems are built to last as well- the CO2 Laser lasts approximately 40,000 marking hours, with the Fiber Laser boasting about 100,000 marking hours. To clarify, this timeframe of “marking hours” represents time spent actually laser marking without stopping.

Consider this example…

Company A is interested in a Fiber Laser system to mark their polyurethane parts, and wants to know how long it will run given these parameters:

- 3 seconds to engrave each part with a detailed mark

- 15 parts per minute

- Two 8-hour shifts each day, yielding 16 hours of operation

- 6 days of operation each week

- 52 weeks of operation per year

If Company A purchased a Fiber Laser marking system from Precision Automation, it would not need any kind of replacement for 23 years.

Regardless of industry- whether you are involved in packaging or pharmaceuticals, dealing with food & beverages, or any consumer product– there is a good chance that the opportunity of laser marking can assist your operation. From printed circuit boards to metals for machined parts and medical and pharma devices, from glass bottles to plastic components, there are endless application examples that can be marked with a laser system.

Contact the integration specialists at Precision Automation today to discuss your specific product and inquire if a CO2 or a Fiber Laser marking system would be the right fit to permanently mark your product!