A Guide to Industrial Laser Marking Machines

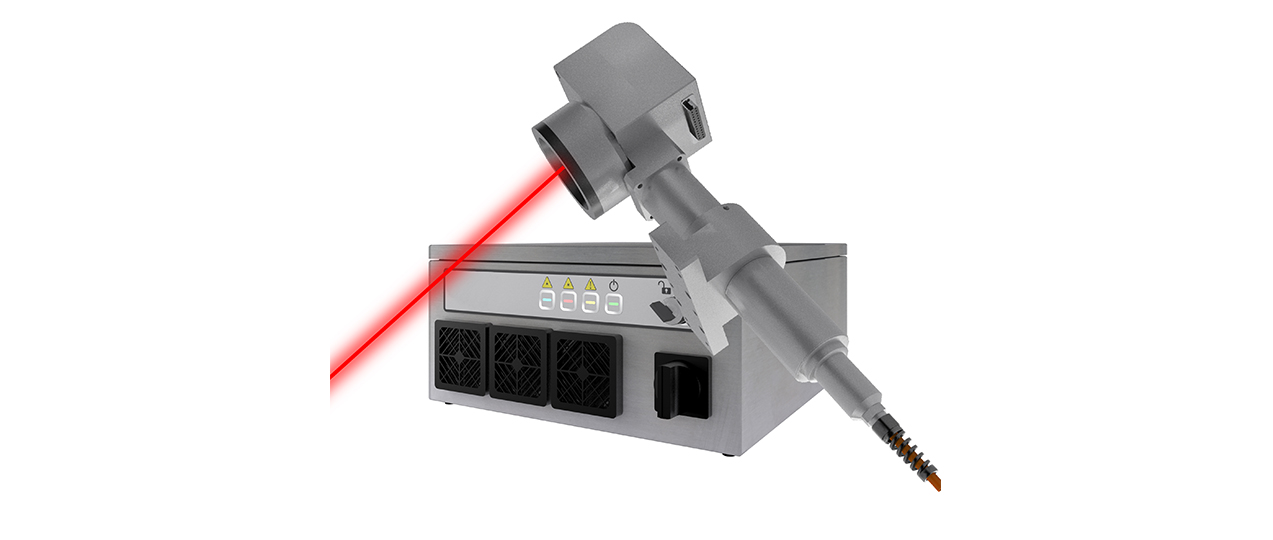

At Precision Automation® Company, we specialize in the manufacture and integration of packaging, processing, and material handling systems. One of our core product specializations is industrial laser marking machines. We offer fiber and CO2 lasers to accommodate different part and production specifications.

Laser marking machines utilize a concentrated beam of light—i.e., laser—to produce permanent markings on the surface of workpieces. Compared to other marking technologies, they offer fast processing speed, produce highly durable markings, and require no down time for replacing consumable materials, all of which makes them ideal for marking a wide range of industrial parts and products.

Advantages of Laser Marking

The terms “laser marking”, “laser etching”, and “laser engraving” are often used interchangeably. However, while they utilize similar technologies, the end results of their operations are different. Both laser etching and laser engraving use lasers to remove a portion of the workpiece material, which causes raised markings in laser etching operations and indented markings in laser engraving operations. In contrast, laser marking uses lasers to form discolorations on the surface of the workpiece, allowing industry professionals to mark components without disrupting the structural integrity of the material.

Compared to other marking methods, laser marking offers a number of advantages. In addition to the above, other advantages include:

-

Material versatility. The laser marking process accommodates a variety of materials, ranging from metal and plastic to leather, glass, wood, and more.

-

Marking visibility and durability. The markings produced in laser marking operations contrast with the material surface, making them easy for both humans and machines to read. Additionally, they are permanent, withstanding exposure to abrasion, chemical, heat, and other harsh environmental conditions that would cause conventional markings to fade.

-

Marking precision, accuracy, and quality. Laser marking technology utilizes a highly focused beam to create precise and accurate markings in various designs and patterns.

-

Marking efficiency. The laser marking process offers greater processing speed than other marking and labeling methods, resulting in time and money savings during marking operations.

-

Environmental friendliness. While traditional marking methods rely on physical labels, chemicals, or inks, laser marking machines directly mark surfaces without the use of additional consumable materials.

-

Customizability. Industry professionals can reprogram or reconfigure laser marking systems to suit changing part and production requirements.

Types of Laser Marking Systems

Laser marking machines are available in several variations. Two of the most common are fiber lasers and CO2 lasers. Fiber lasers are a type of solid-state laser (i.e., the active laser medium is solid), while CO2 lasers are a type of gas-state laser (i.e., the active laser medium is gaseous). The former utilizes optical fibers laced with rare-earth minerals (e.g., ytterbium or neodymium) to generate, transmit, amplify, and focus a beam of light, while the latter relies on a CO2 gas mixture to produce the laser beam. Fiber lasers offer greater power than CO2 lasers, making them suitable for marking metals and plastic materials. CO2 laser systems are better suited for softer, organic materials such as glass, leather, and wood.

Industrial Applications of Laser Marking Machines

Laser marking machines are used in the day-to-day operations of a wide range of industries, including:

-

Medical/Pharmaceutical. Laser marking is used in the medical and pharmaceutical industries to produce markings that can withstand disinfection and sterilization processes. It is one of the preferred methods for adding important information to various equipment, such as surgical tools, syringes, implants, and packaging.

-

Food and Beverage. Food and beverage companies use laser marking to label packaged products—ranging from cardboard containers to sealed sachets—with lot numbers, batch codes, expiration dates, and other important information. While traditional labeling methods use materials that are toxic and tend to smear, laser marking creates non-toxic, smudge-proof, and easy-to-read markings.

-

Bottles/Cans. High-speed laser marking systems streamline the coding and labeling processes in bottling and canning operations. For example, the beverage industry commonly uses laser marking machines for labeling glass and plastic bottles, aluminum cans, and other types of beverage containers.

-

Consumer Goods. From personal care items to cleaning products, the appearance and presentation of consumer goods packaging can have a significant influence on the customer’s purchasing decision. Laser marking machines offer an effective solution for creating high-quality barcodes, serial numbers, copyright/trademarks, logos, and other markings on packaging in a way that will not detract from the overall aesthetics of the product.

-

Manufactured/Machined Parts. In the manufacturing industry, laser marking is a reliable and efficient way to add permanent marks to parts made from virtually any type of material. Laser marking machines are often used to add QR codes, serial numbers, barcodes, or logos that can be used for part traceability, quality control, and process improvement.

-

Packaging. Laser marking is a cost-effective method for adding precise and accurate markings to a variety of common packaging materials, including paper, plastics, organics, and textiles. Unlike traditional labeling methods, laser marking creates easy-to-read labels that will not peel off or smudge over time.

Custom & Turnkey Laser Marking Solutions at Precision Automation®

The sales engineering team at Precision Automation® provides industry-leading labeling and marking systems for a wide range of industrial applications. Our complete system solutions are reliable, flexible, and durable. They can be configured with a variety of technologies, including laser markers, to suit virtually any labeling and marking needs.

Our Arca laser marking systems offer high-speed and high-quality permanent marking capabilities. They are compact, cost-efficient, and long-lasting. Additionally, they come with a life expectancy of up to 100,000 hours of marking time with little to no maintenance costs. By offering fiber and CO2 laser options, we ensure the marking and labeling systems that we deliver accommodate all of our customers’ material requirements, including metal, plastic, ceramic, glass, wood, leather, (even cheese!) and more.

To learn more about our custom labeling and marking solutions or discuss your application requirements with one of our experts, contact us today.