Panel Building: Optimizing Control Panel Design and Construction

At Precision Automation, we are constantly looking for new ways to optimize the control panel building process. We understand that by reducing the amount of time and materials that go into each project, the overall cost of control panel design and construction is also reduced. Through optimizing control panel building, Precision Automation presents our customers with the best possible value for their money. Discover the many strategies our team uses to accomplish this feat of efficiency:

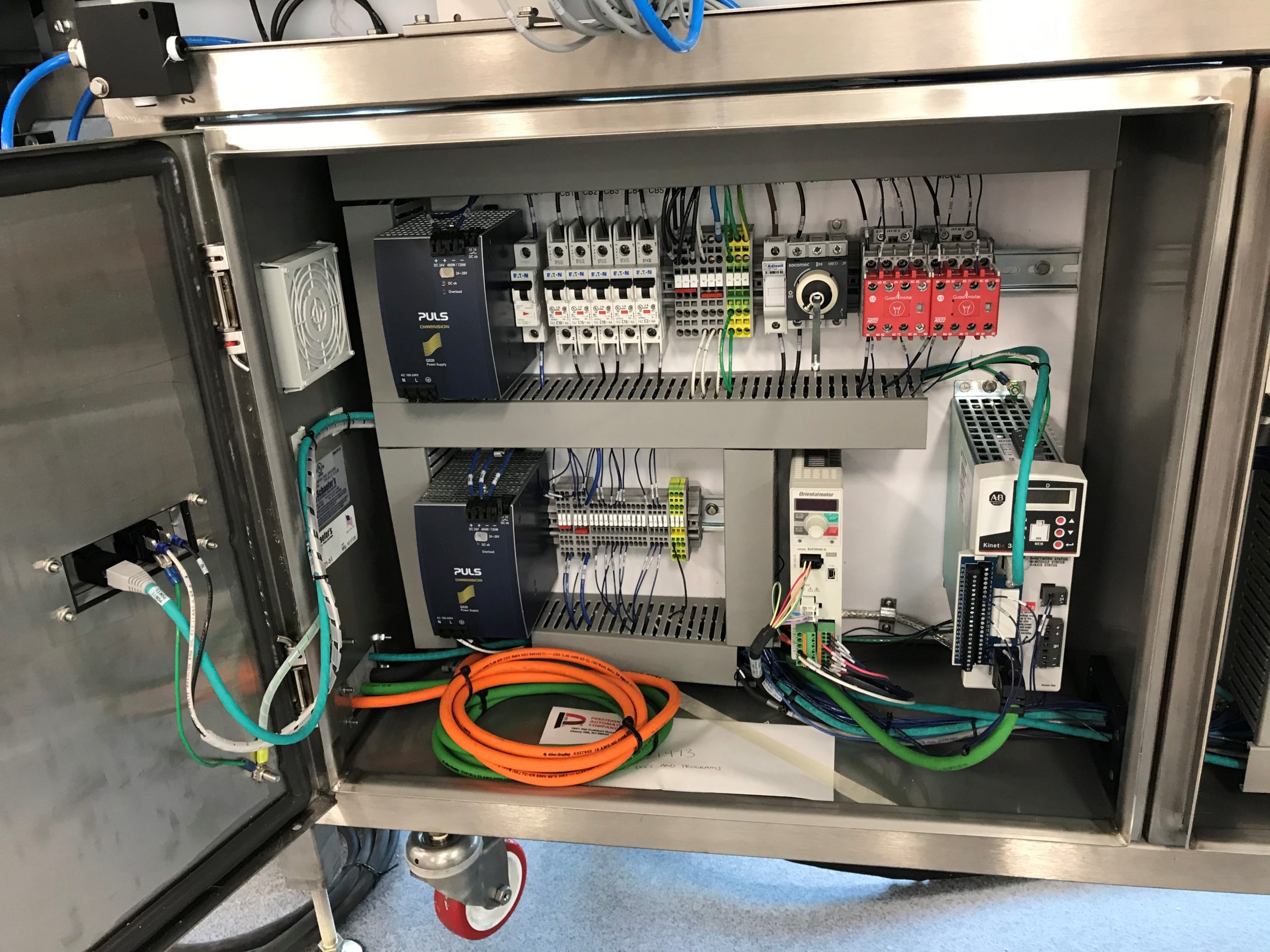

Standardized Layouts for Control Panel Builds

With the help of our outstanding design team, Precision Automation assists our customers by finding ways to streamline the control panel building process. This optimization process may involve standardizing electrical enclosure layouts, whether that means replacing hardwired pushbuttons with touchscreen controls or implementing spring-cage terminals instead of standard screw terminations. By standardizing the control panel builds, wiring time can be reduced further, ultimately saving time and money, all while retaining excellent quality.

Implementing Control Panel Diagnostics

One simple way to increase the efficiency of control panel builds is to implement control panel diagnostics. By integrating a way to analyze common control panel issues, customers are able to have complete control over their equipment. This process often eliminates costly site visits in the long run and optimizes workflow.

Reducing Control Panel Build Times with Device-Level Wiring System

When it comes to optimizing build time for control panels, a device-level wiring system can be game-changing. These types of systems can not only be used to significantly cut down on wiring time, but the engineering and testing times can also be reduced. By spending less time on repetitive or unnecessary tasks, Precision Automation reduces labor costs and our team is able to deliver our products in a timely manner.

Less Complex Control Panel Builds Using Point-to-Point Wiring Techniques

Establishing point-to-point wiring practices also optimizes control panel building projects because these strategies reduce time spent on testing, increase productivity, and improve cost-efficiency. These advantages are made possible because less wiring means lowering the risk of mistakes during control panel builds, and less time is needed to check the integrity of each control panel.

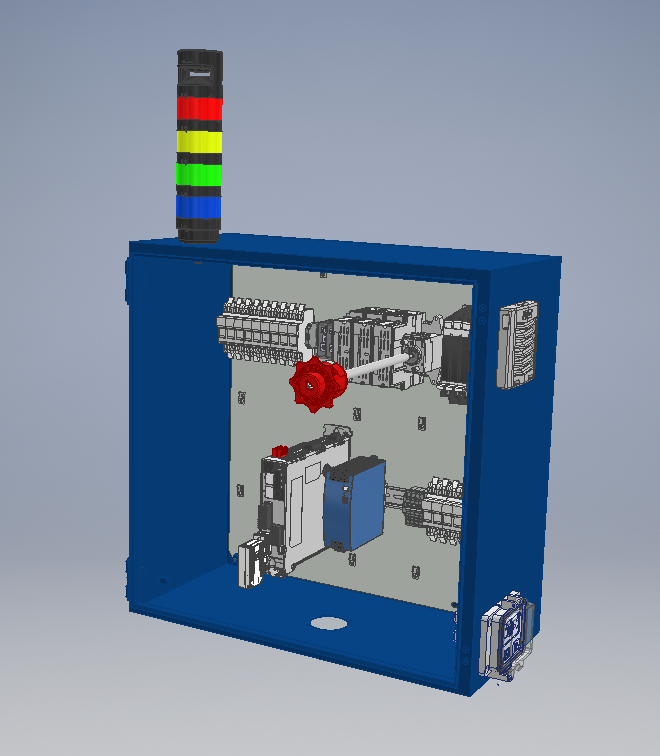

Building 3D Control Panels

Three-dimensional control panel designs optimize projects in two ways. Firstly, material costs are reduced by building control panels to fit within specific parameters and eliminating excess cables. Secondly, by taking advantage of accurate dimensioning, 3D control panels save space for our customers as well. Instead of planning around the shape of your control panel, plan your control panel design around your larger project requirements!

Optimize the Control Panel Building Process with Precision Automation

Perhaps the most important way our customers can guarantee optimized control panel design and construction for themselves is by investing in a company that is thoroughly experienced and equipped for these exact types of projects. At Precision Automation, you can trust that we have already encountered every common challenge that the industry throws at control panel builders. With years of design and construction knowledge at our command, we are confident that we can streamline any project while meeting your highest standards for quality.