Automation Solutions for the Pharmaceutical Industry

The pharmaceutical industry is constantly evolving and growing. With the frequent development of new technologies, companies need to adapt and find ways to harness that technology for maximum efficiency. Subsequently, the automation & manufacturing companies that provide pharmaceutical systems and services are constantly improving their capabilities to support.

For businesses that fail to employ these technologies, the introduction of new pharmaceutical products may take years instead of weeks, and they will likely fall behind to their competition. Companies that grasp these initiatives and implement solutions stand to gain the largest advantage, allowing them to operate faster, more cost-efficient and fully compliant.

Powering Pharmaceutical Manufacturing Processes

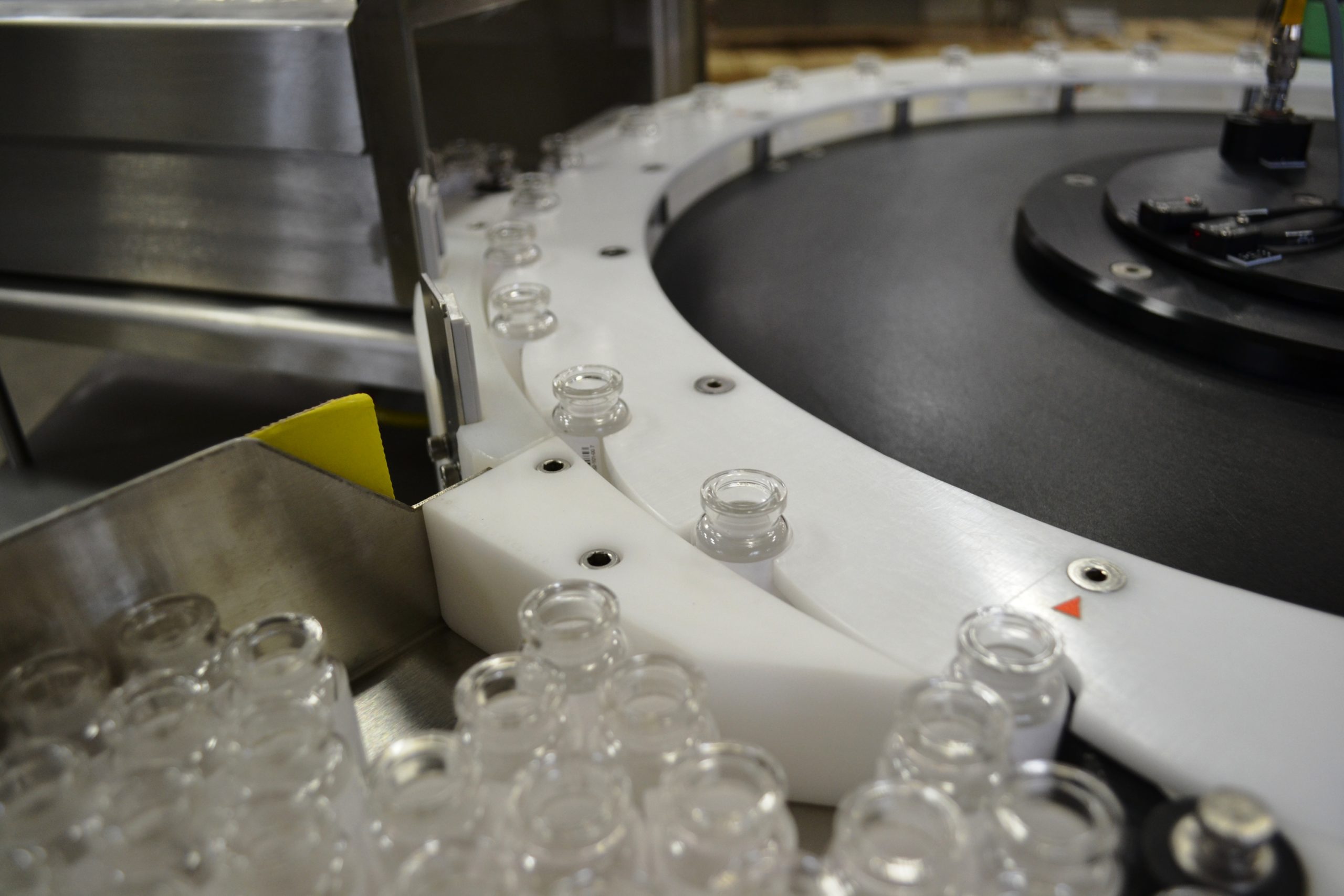

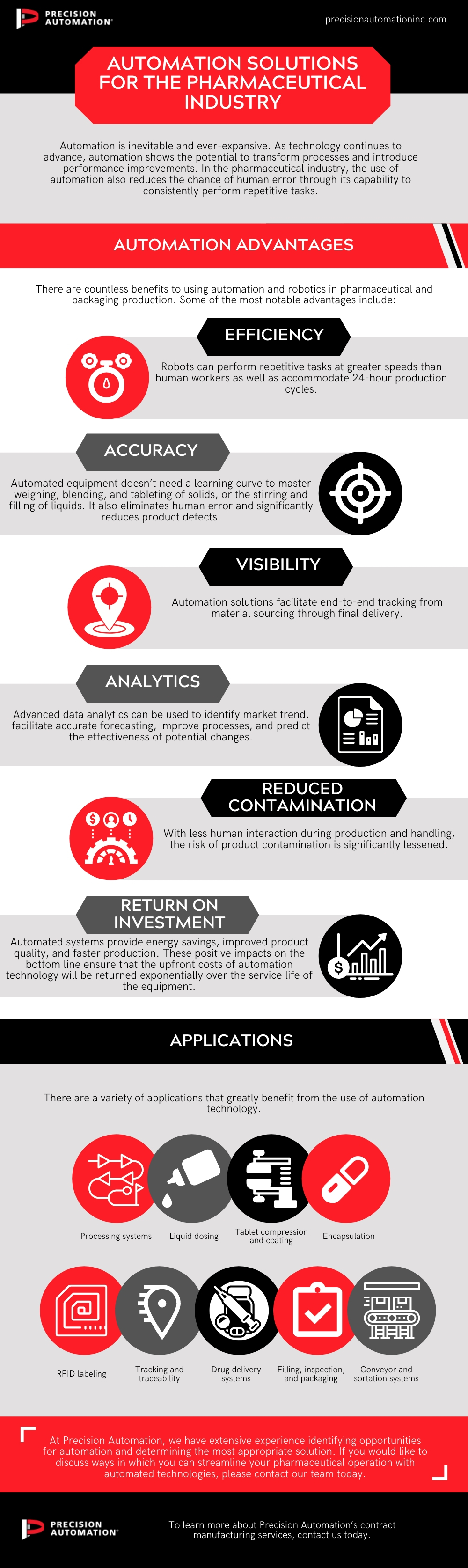

Automation is inevitable and ever-expansive. As technology continues to advance, automation shows the potential to transform processes and introduce performance improvements. In the pharmaceutical industry, the use of automation also reduces the chance of human error through its capability to consistently perform repetitive tasks. Pharmaceutical companies have been integrating automation into specific processes like drug development, serialization, anti-counterfeiting, and more. In manufacturing examples, automation has become prevalent in processes such as kit assembly, sortation, machine tending, and packaging.

Automation Advantages for the Pharma Sector

There are countless benefits to using automation and robotics in pharmaceutical development and production. Some of the most notable advantages include:

-

Efficiency. Robots can perform repetitive tasks at greater speeds than human workers alone. Automated solutions can also accommodate 24-hour production cycles, and are typically easy to implement.

-

Accuracy. Automated equipment doesn’t need a learning curve to master weighing, blending, and tableting of solids, or the stirring and filling of liquids. Automation eliminates human error and significantly reduces product defects.

-

Visibility. Automation solutions facilitate end-to-end tracking from material sourcing through final delivery. Electronic batch records, RFID technologies, and workflow management can help identify inefficiencies and correct them anywhere in the supply chain.

-

Analytics. Advanced data analytics can be used to identify market trends and facilitate accurate forecasting. Analytics can also be implemented to improve processes and predict the effectiveness of potential changes.

-

Reduced contamination. With less human interaction during production and handling, the risk of product contamination is significantly lessened.

-

Return on investment. Automated systems provide energy savings, improved product quality, and faster production. These positive impacts on the bottom line ensure that the upfront costs of automation technology will be returned exponentially over the service life of the equipment.

Pharmaceutical Automation Applications

There are a variety of industry-specific applications that greatly benefit from the use of automation technology. Here are some examples:

-

Processing systems (dry granulation, power blending, high shear/wet granulation, fluid bed granulation, hot melt extrusion, drying, milling, micronization)

-

Liquid dosing (used in tablet manufacturing)

-

Tablet compression and coating

-

Encapsulation (solid and liquid dosages)

-

RFID labeling (product movement monitoring, quality management)

-

Tracking and traceability (counterfeit prevention)

-

Drug delivery systems

-

Filling, inspection, and packaging

-

Conveyor and sortation systems (high speed bottle filling, inspection, sorting and grouping, rejection and transferring)

Pharmaceutical Automation Systems from Precision Automation

At Precision Automation, we have extensive experience identifying opportunities for automation and determining the most appropriate solution. We are a one-stop shop for turnkey custom automation solutions that improve efficiency and cut costs. If you would like to discuss ways in which you can streamline your pharmaceutical operation with automated technologies, please contact us today.