Understanding Precision Labeling & Marking Solutions

Automated labeling systems apply labels to products, cases, and containers as part of the production process. In assembly line setups, for example, the automatic labeling system will receive a steady input of products, apply the label in-line, and convey the product to the next step in the production line. Automated labeling machines are easily integrated into larger automated processing and packaging systems. Additional equipment such as vision systems can communicate with the line control to actively signal if a product has been labeled or has an error, and passively receive signals that an item is ready for labeling.

There are different types of automated labeling machines, differing from manual and semi-automatic labelers to high-speed in-line systems. In this article, we’ll discuss the value of precision labeling solutions in industrial processes, the benefits of marking solutions, and why your facility should consider them for its operation.

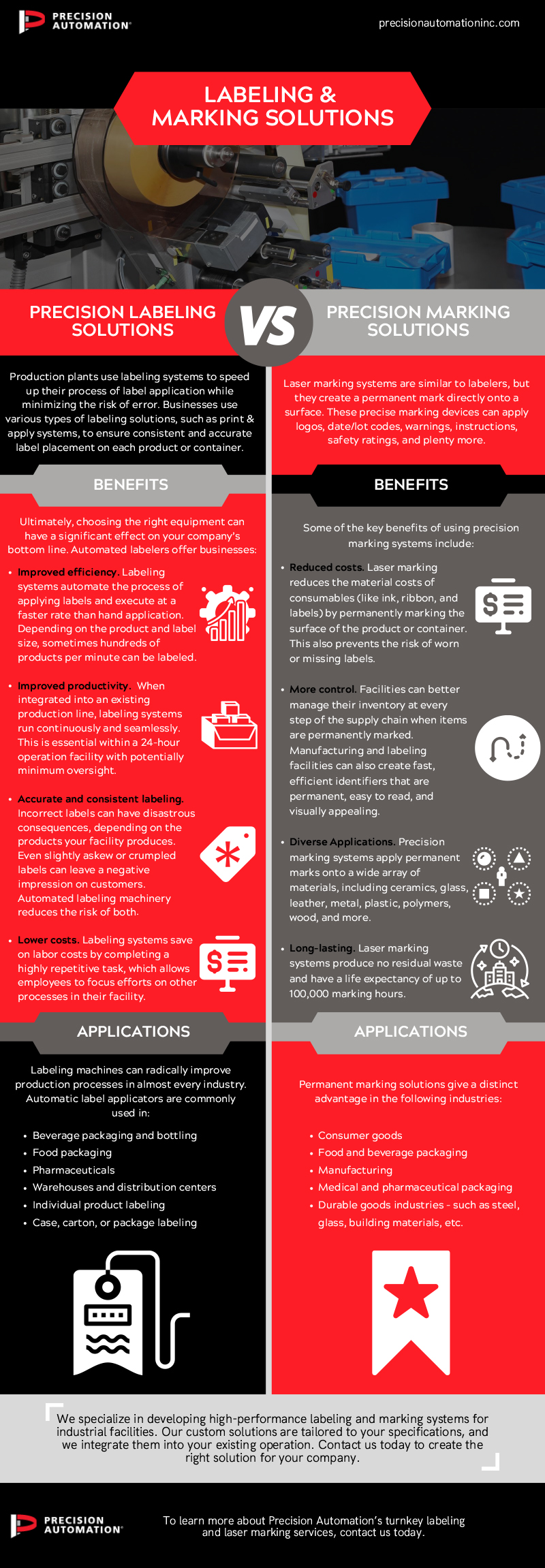

Precision Labeling Solutions

Production plants use labeling systems to speed up their process of label application while minimizing the risk of error. Businesses use various types of labeling solutions, such as print & apply systems, to ensure consistent and accurate label placement on each product or container. Labels can include marketing materials and branding, barcodes and unique identifiers, safety warnings and instructions, and more. Using these solutions instead of relying on manual application improves a business’s productivity and functional output.

4 Financial Benefits of Integrated Labeling Systems

Ultimately, choosing the right equipment can have a significant effect on your company’s bottom line. Automated labelers offer businesses:

- Improved efficiency. Labeling systems automate the process of applying labels, and execute at a faster rate than manual application. Depending on the product and label size, sometimes hundreds of products per minute can be labeled.

- Improved productivity. When integrated into an existing production line, labeling systems run continuously and seamlessly. This is essential within a 24-hour operation facility with potentially minimum oversight.

- Accurate and consistent labeling. Incorrect labels can have disastrous consequences, depending on the products your facility produces. Even slightly askew or crumpled labels can leave a negative impression on customers. Automated labeling machinery reduces the risk of both.

- Lower costs. Labeling systems save not only on labor costs but by reducing the risk of expensive on-the-job injuries that occur from highly repetitive tasks. Automatic labeling systems are faster, more efficient, and less prone to error, all of which have a positive impact on the bottom line.

Customization Options

You can specify or even customize a labeling system that best fits the needs of your production process. Some of the most popular customizations include:

- Any combination of label application on products such as front/back, top/bottom, cylindrical wraps, corner wraps, and more.

- Print & apply systems that can apply variable data, barcodes, and addresses.

- Date/lot codes via inkjet, laser marking, hot-foil, or other marking systems.

- Inspection systems for built-in quality assurance.

Industrial Applications

Labeling machines can radically improve production processes in almost every industry. Automatic label applicators are commonly used in:

- Beverage packaging and bottling

- Food packaging

- Pharmaceuticals

- Warehouses and distribution centers

- Individual product labeling

- Case, carton, or package labeling

Precision Marking Solutions

Laser marking systems are similar to labelers, but they create a permanent mark directly onto a surface. These precision marking devices can apply logos, date/lot codes, warnings instructions, safety ratings, and more. Laser marking is an alternative to labels for items that need permanent identification and are typically used in the durable goods market.

Benefits of Precision Marking Equipment

Some of the key benefits of using precision marking systems include:

- Reduced costs. Laser marking reduces the material costs of consumables (like ink, ribbon, and labels) by permanently marking the surface of the product or container. This also prevents the risk of worn or missing labels.

- More control. Facilities can better manage their inventory at every step of the supply chain when items are permanently marked. Manufacturing and labeling facilities can also create fast, efficient identifiers that are permanent, easy to read, and visually appealing.

- Diverse Applications. Precision marking systems apply permanent marks onto a wide array of materials, including ceramics, glass, leather, metal, plastic, polymers, wood, and more.

- Long lasting. Laser marking systems produce no residual waste, and have a life expectancy of up to 1,000 marking hours.

Permanent marking solutions give a distinct advantage in the following industries:

- Consumer goods

- Food and beverage packaging

- Manufacturing

- Medical and pharmaceutical packaging

- Durable goods industries- such as steel, glass, building materials, etc.

Custom and Turnkey Options

Labeling and marking systems can be integrated into a variety of different automated system configurations. For example, facilities can integrate the systems for printing and labeling within a single step, or integrate marking and labeling into the production line before final packaging. Manufacturers can also augment labeling or marking systems with inspection tools to ensure the product is adequately and accurately labeled.

At Precision Automation, we offer a diverse array of turnkey options using Arca solutions, including:

- End of line printing and applying.

- Inkjet and laser marking.

- Primary product, RFID, and shipping labeling systems.

- Robotics, including articulated arm, collaborative, gantry, and SCARA devices.

- Systems that integrate packaging, labeling, and processing

Request Your Custom Systems from Precision Automation

We specialize in developing high-performance labeling and marking systems for industrial facilities. Our custom solutions are tailored to your specifications, and we integrate them into your existing operation. Contact us today to start creating the right solution for your company.