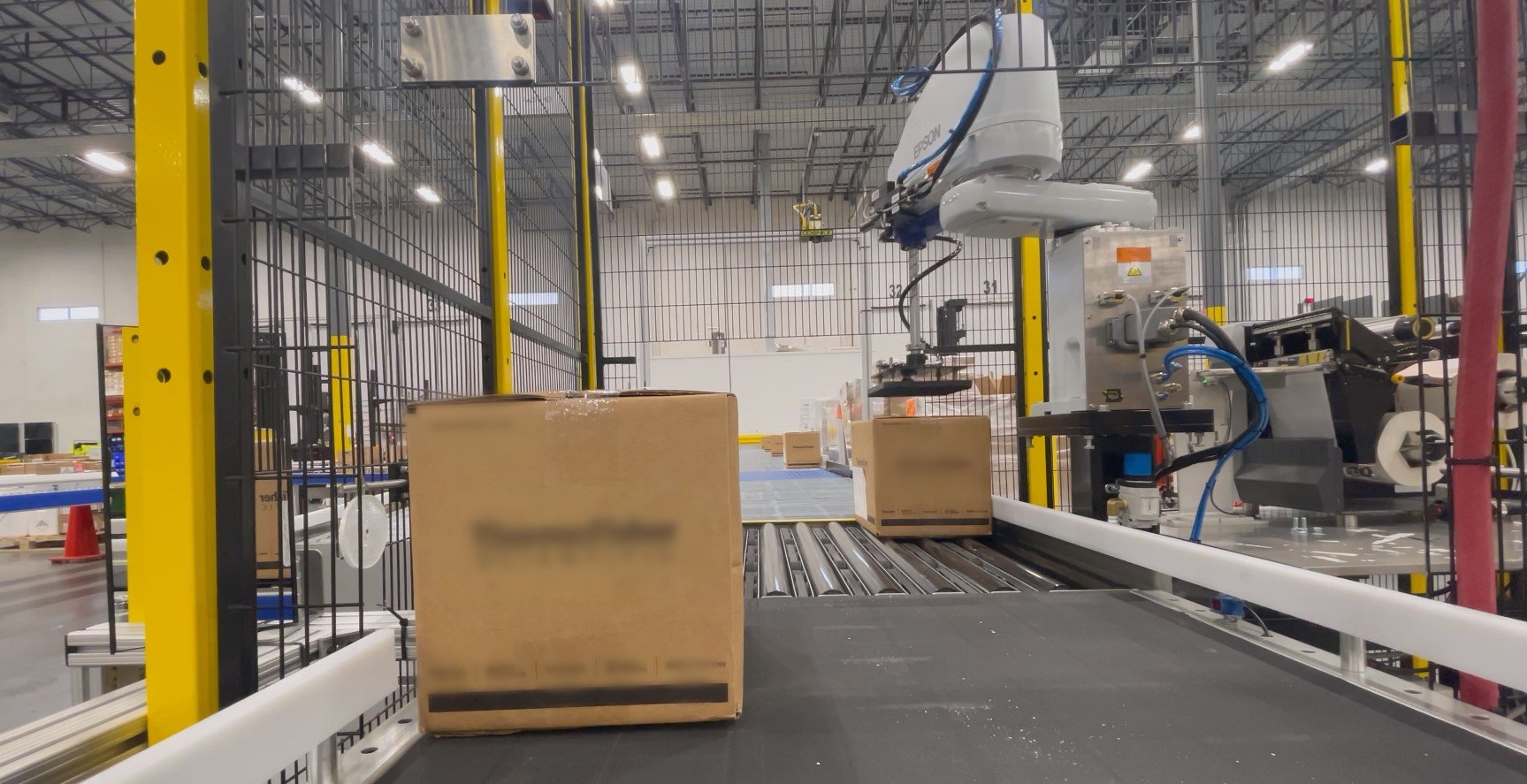

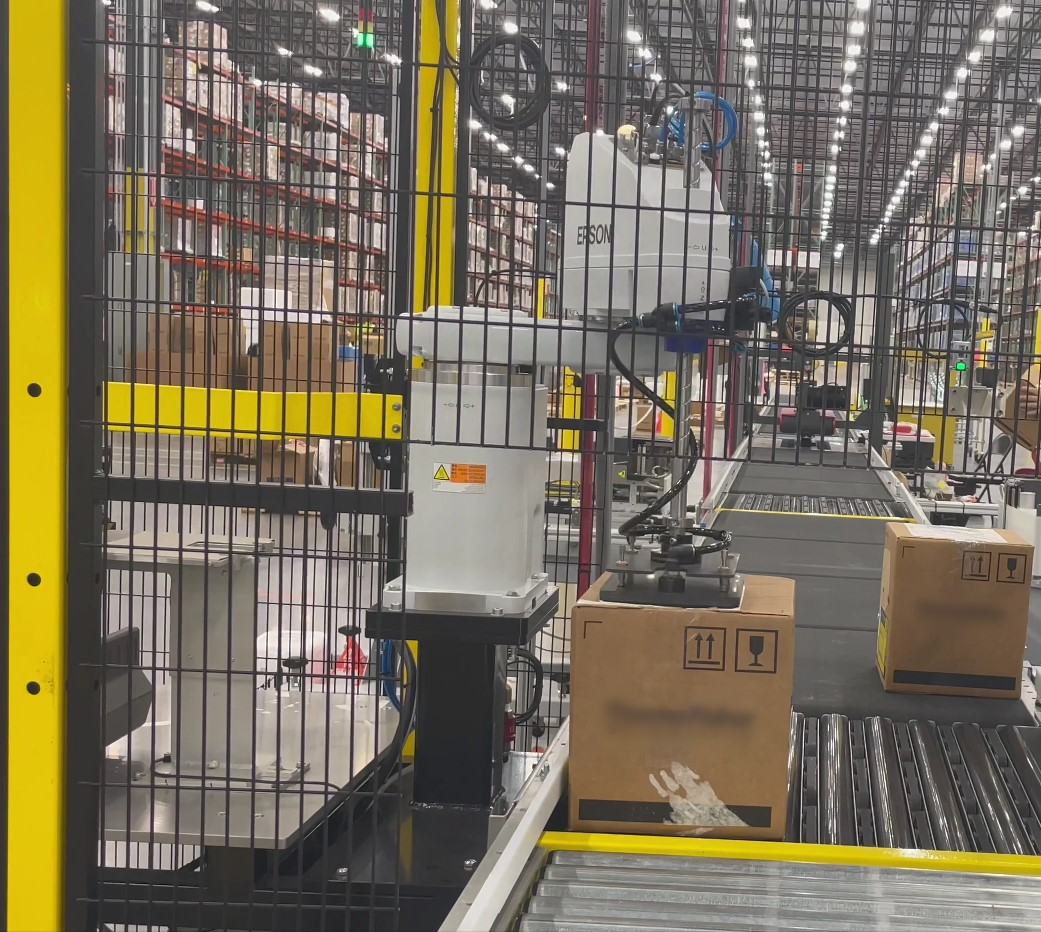

Robotic and Labeling Automation Work Cell

Smart companies consistently seek improvements to their packaging processes with new innovations or upgraded processes. With robotic improvements ushering in more unique opportunities for integration every day, a new way to label packages is here to showcase the seamless integration of print & apply labeling and robotic automation.

Multiple Sheets of Packing List

Precision Automation® has teamed up with our colleagues at Chicago Tag & Label, Inc. (CTL) to present our customers with an easy all-in-one method of printing multiple sheets of label and applying them to a case in a single motion. Using cutting edge technology and Chicago Tag’s patented Multiplex™ label, printing and applying detailed labels to packages has never been easier.

The original MultiPlex™ solution offers an easy, tearaway shipping label with enclosed packing list. The idea behind this specialized label was to eliminate the need for extra packing slip pouches to constantly have to be hand-applied to the outsides of outgoing packages. While that revolutionized the labeling process, it was limited to only two or three sheets. This new robotic and labeling automation work cell offers more flexibility if a package requires more sheets as part of its built-in label.

In addition to CTL’s blog, Packaging World wrote a snippet about this new solution last month and highlighted the time-saving effect it would have on an end user’s operation. In addition to crediting both CTL and Precision Automation in the collaborative effort, the article also gives credit to Epson and Zebra for their respective systems’ inclusion in the automation design.

Not Your Everyday Print & Apply

This solution begins with order fulfillment where parts are packaged into cases and sealed, and an internal “license plate” style label is applied to the case which communicates the contents, shipping address, and other pertinent details via vision sensors. The system’s HMI (Human Machine Interface) then relays the information to the Zebra ZT620 which prints out the packing slip in as many sheets as required, depending on the contents of that case.

What sets this turnkey solution apart from other print & apply labeling systems is the Epson GX-Series SCARA robot that picks up the entirety of the packing list off the printer tray at once, and then applies it to the respective case in one motion. The Precision Automation® engineering team had programmed the robot to work with cases of various sizes, and to place the adhesive packing slip onto the case in the same position (relative to the package’s leading edge) every time.

This solution delivers the end-user customer a fully automated order fulfillment process which ultimately reduces their costs, streamlines the packaging process, and increases the facility’s overall efficiency. You can find the announcement about this complete solution in DC Velocity as well.

Contact Us for More Info

If you have interest in this particular solution, or another type of robotic and/or labeling system, feel free to contact us today and inquire about our automation solutions. Our sales engineers would be happy to start an introductory conversation to learn more about your specific operation & environment, and how our automation integration can best answer your packaging needs.