Robotics within the Food & Beverage Industry

Recently in this blog, we have discussed robotic solutions in collaboration with labeling systems as well as how they assist warehouse operations. But we have not yet dived into how robotic integration can positively enhance companies within the food & beverage industry.

An article published this past summer from Robotics Tomorrow magazine tackles this topic by taking an in-depth look at 7 Reasons Robots Make a Huge Difference in Food Processing. We are going to explore just a few of these reasons and highlight how impactful a robotic integration solution can be to a business looking to improve safety, address labor demands, and achieve higher throughput.

According to the CDC, approximately one in six American citizens get sick via foodborne illness each year. With a figure so staggering, it is apparent that food processing companies would seek to do everything possible to minimize those consequences. Remaining in one place and not traveling to & from the facility, robots cannot catch diseases and/or transport contaminants that initially cause illnesses. By utilizing a robotic system (and maintaining its cleanliness and sanitization) a company in this field can reduce the amount of cross-contamination, and thus: the impact on the public health.

Like plenty of other businesses across all industries, food & beverage processing companies deal with more than their fair share of labor shortages. The struggle to find reliable employment is shared by many, and this gap opens the door for robotic integration to answer the need. The robotic solutions that Precision Automation® provide are not intended to replace employees, but rather: execute the repeatable automated tasks. This way human labor can focus efforts on more engaging, complex tasks while the robot continues its programmed motion.

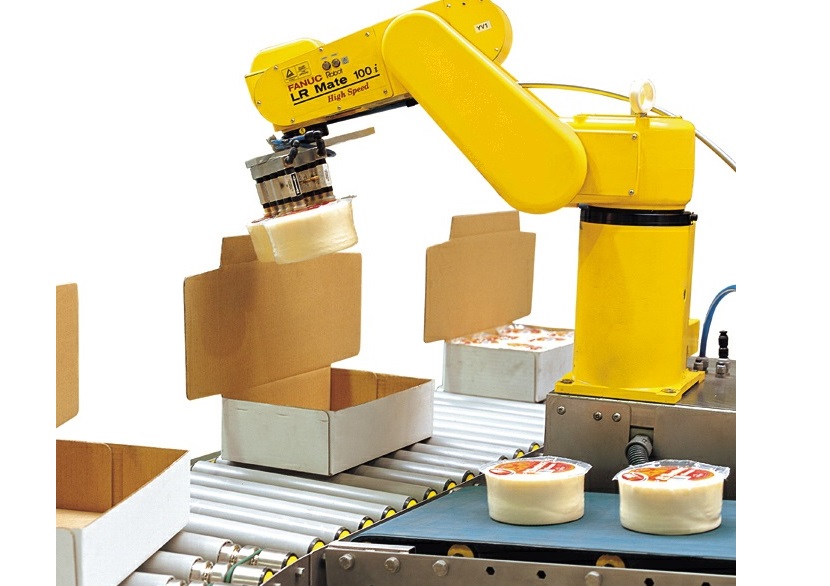

Finally, robotics within the food & beverage industry typically operate faster than the human hand (and more accurately) which results in higher production rates. The most common thought process when picturing this scenario is likely a robot flipping & serving hamburgers; but that is just one specific, albeit somewhat popular, example. There are countless examples of robotic systems- outfitted with a seemingly endless variety of end-effectors- being programmed to take on menial tasks too often assigned to employees.

Be it picking & placing, sorting, filling, capping, slicing, dicing, or even packaging items at the end of a production or processing line: robotic systems are here to assist. And Precision Automation® offers a one-stop shop to tailor a complete robotic solution to your specific food or beverage processing plant. We are fully equipped with the experience, industry knowledge, and design capabilities to integrate a solution that is specifically designed to boost your efficiency and create a safer work environment for all involved.

Should you have an application that would benefit from this kind of robotic integration, do not hesitate to contact us today. Our team of sales engineers are ready to have a conversation with your facility director or manager and understand more about your specific operation. Once we learn about the target space and hygienic environment details, we look forward to providing a complete solution that would work best to fulfill your food processing needs.