Sustainability for End-of-Line Packaging

One of the latest widespread trends in the manufacturing and packaging industry is sustainability. Almost every trade publication in the last year or 2 had featured an article discussing the importance of sustainability, especially as it pertains to a company’s ecological footprint. But many companies might ask: how can we become more sustainable without overturning our entire process? In this blog, we’ll take a look at two articles and an industry study examining sustainability and how packaging operations can create a positive impact.

End-of-Line Packaging

In a manufacturing production environment, the collection of machinery that completes the packaging process prior to final shipment is called end-of-line (EoL) packaging. This includes everything from conveyance, to palletizing, stretch-wrapping, labeling, and any other equipment that completes finalizes packing before transportation. The purpose of EoL packaging is to keep intact the products/materials being produced & parceled from when they leave the origin facility until they reach their destination and are properly disassembled.

This article from Sterling Anthony in last month’s issue of Packaging World magazine discusses EoL packaging, and its importance in the modern supply chain world. This importance is not shrinking either; Verified Market Research projected that EoL packaging market size will reach $6.4 Billion by 2028, yielding a compounded annual growth rate of 4.25% from 2020. While each company evaluates how much automation is feasible for their individual operation, it is apparent that a completely manual EoL packaging process is not a long term option. Mr. Anthony states: ”Even when upstream operations are devoted to a single product, volume can increase over time, putting pressures on EoL packaging that are best addressed through automation.”

Packaging Design for Sustainability

Now more than ever before, businesses are packaging their products with recycling and reusability in mind, and this has been just one phase of a growing push for sustainability. Still, some of those companies that prioritize sustainability into their process run into issues with availability and consistency of recycling methods. Therefore, it becomes far easier and cheaper to select a simpler, one-time-use method of packaging which may be counterintuitive to their sustainability goals.

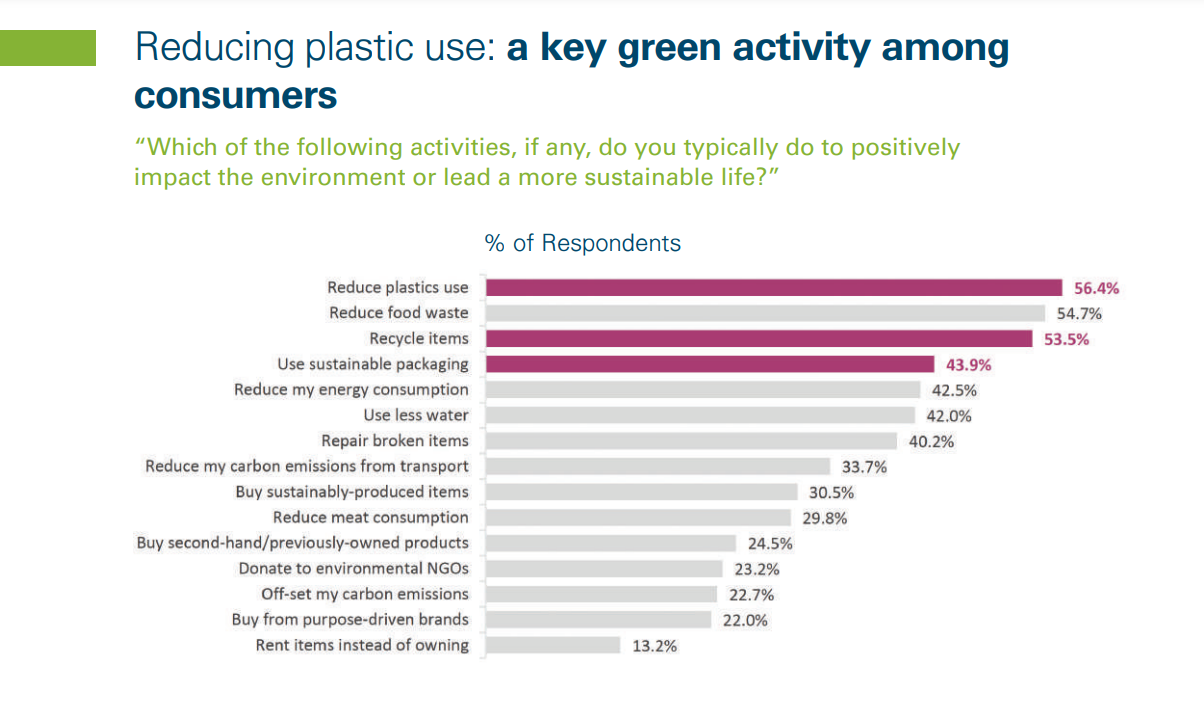

PMMI (of which Precision Automation® is a member) released a study last year taking an in-depth look into sustainability in packaging, and how it affects customers’ buying tendencies. According to the study, “44% of consumers use sustainable packaging” with the strong majority of respondents focusing on recyclable, biodegradable, or refillable/reusable types of packages.

Sustainability in packaging (particularly when discussing EoL operations) comes with its own set of challenges beyond resource availability. The cost of sustainable resources is something to weigh within a consumer packaged good (CPG) company’s own budget allowances, as is the manufacturing production environment. Pivoting from a glass container (which typically requires more energy to manufacture) to a paper or cardboard container may seem like a sustainably positive move- unless the product’s quality is negatively affected, or the container’s integrity is compromised by the product itself.

The Sustainable Future of Packaging

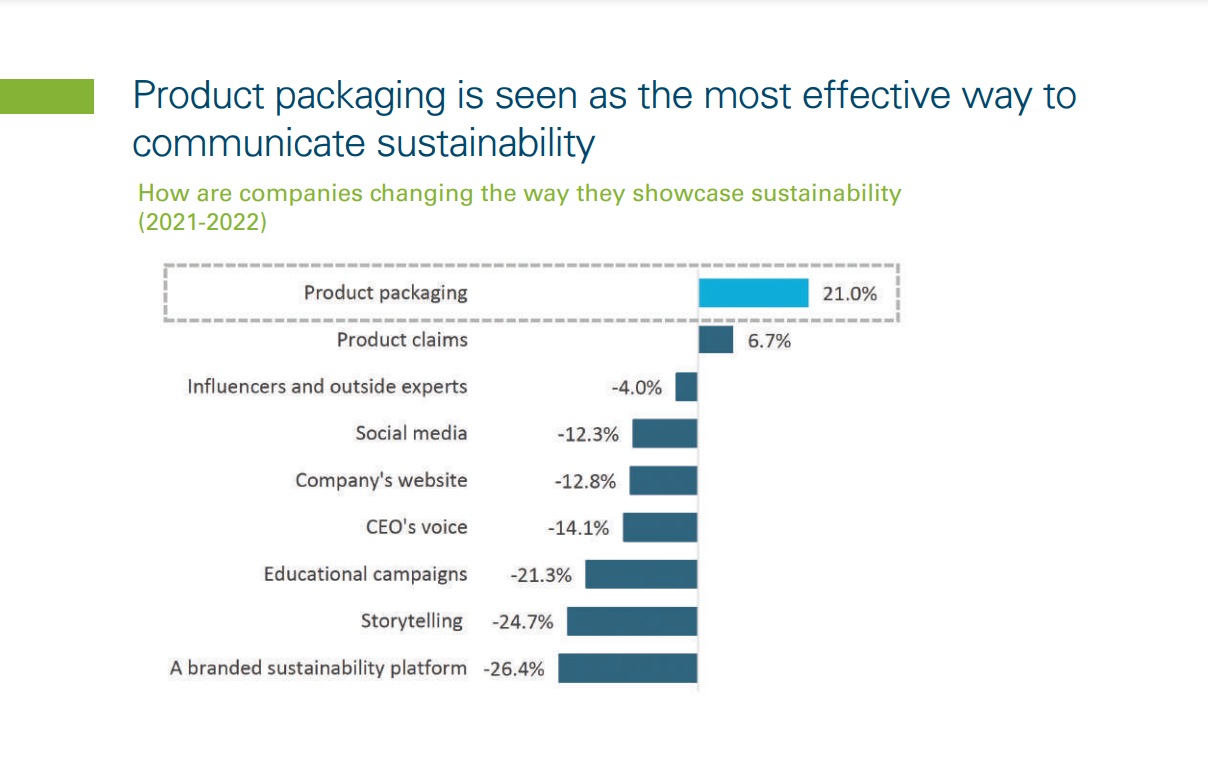

The publication Packaging Technology Today took a closer look at PMMI’s study in last month’s issue in their article The Future of Packaging and Sustainability. The piece discusses different ways CPG companies are changing the way they operate to produce less waste while still maintaining a competitive edge without totally upending their current processes.

As a result of the pandemic, the packaging industry has seen an overall increase in demand for CPGs and, paralleling the patterns identified by the PMMI study, countless manufacturers have committed to strategic alterations. While plastic is still the dominant choice for the packaging of products, there has been a significant uptick in manufacturing use of post-consumer recycled (PCR) plastic, which is essentially a material made from the molded remains of normally recycled items.

The chart above (from the PMMI study) showcases the different ways that consumers get involved to try and positively impact their footprint, with ‘reducing plastic use’ being the majority leader. This goes hand-in-hand with the rise of PCR plastics, along with the increased number of beverage manufacturing companies allowing & encouraging their customers to use refillable containers when purchasing coffee, tea, or soda drinks.

How Precision Solutions Can Help

The industry’s top manufacturers are leading the charge toward a more sustainable future, so what can a smaller company like Precision Automation® do to make an impact? For one, we have applied to be a part of PMMI’s Pack Expo GREEN program with a commitment to create and further a more sustainable world. Aside from our day-to-day commitment to paper recycling, our organization emphasizes re-usage of shipping packages, and we have been using motion sensor lights throughout the office to reduce electrical waste.

When it comes to our automation solutions, we plan to display a Linerless print & apply labeling system as part of our Pack Expo 2023 booth exhibit. This unique Arca labeling solution yields zero waste compared to the larger models that house a separate reel for the label liner- and it does not compromise speed or print resolution. An ecological solution that still proves efficient as ever, the new Linerless 4.0 offers innovative touchscreen HMI complete with smart range monitoring.

If you are looking to eliminate the use of labels entirely, our laser marking systems do not use any consumables by etching information directly onto your product or package. Between the CO2 and Fiber Laser systems, you have the capability to mark onto variably any type of surface material in a clear, legible, and fast manner.

Feel free to contact us today and inquire about how our solutions can enhance your operation’s sustainability. Our team is eager to hear more about your process so we can begin designing and implementing the perfect solution for your manufacturing needs, while we all try and look out for the greater good of this Earth.