Top Three Advantages of Robotic Integration Solutions

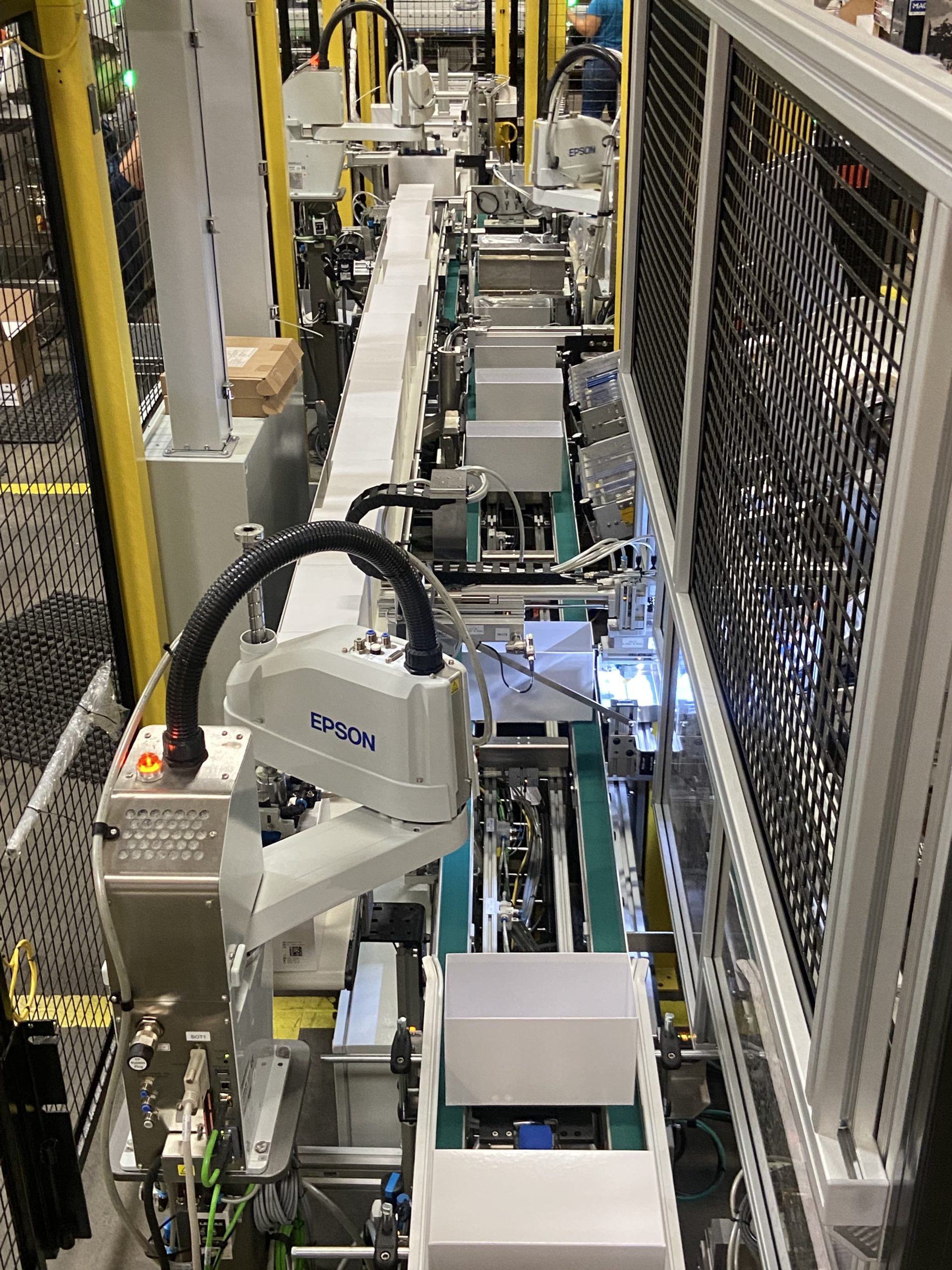

As a thoroughly experienced manufacturer and designer, Precision Automation® specializes in adapting to our customers’ various needs, and serving a wide range of industrial sectors. This includes services such as robotic automation, and we have partnered with companies like Epson and Fanuc to create custom robotic solutions for our customers.

While our organization is upfront about our ability to increase production efficiency and decrease operational costs, you may be looking for a detailed explanation for how these feats are accomplished. Fortunately, Precision Automation® is a transparent company with many compiled examples of our turnkey robotic solutions in action which demonstrate our ability to meet our customers’ needs.

Robotic Solutions for Flexibility

Complex robotics systems and software can handle a wide variety of materials and requirements. For example, our company has extensive experience working with clients within the food and beverage industry. During our work with this market, we have found that customers often require an automated system that is capable of handling non-uniform food products, such as produce. Because our robotic solutions are equipped to handle changing variables, our food and beverage customers do not have to worry that one irregular product will result in production downtime or damaged goods.

Precision Automation® provides additional flexibility through the scalability of our robotic solutions. Selective Compliance Articulated Robot Arm (SCARA) robots are particularly well-equipped to adjust to growing production demands due to their ability to move about the X, Y, and Z axes at high speeds. Often useful in those scenarios is a combination of the IntelliFlex vibratory separator system with integrated camera, which offers vision-guided product separation & handling.

Additionally, the flexibility of our robotic systems allows us to meet evolving industry needs. When a customer required an integrated packaging solution during the COVID pandemic, our team was able to utilize SCARA robotics in three unique ways to achieve this goal.

Reduced Labor Costs, Increased Accuracy

Because machines do not run the risk of fatigue or distraction that humans do, robotic solutions not only decrease labor costs, but also increase the accuracy and consistency of production processes. An example of this robotic solution at play is found in the Pharmaceutical Processing & Packaging industry. These customers, even more so than other packaging customers, require utmost precision when it comes to the handling of their products. Because of this, Precision Automation® understands the necessity of not only developing a robotic solution that would mechanically behave as a human handler, but also to design an overall system that presents the handled part or product in a consistent manner, through each process cycle.

One of the many bio-mimicking devices that our team has implemented into a turnkey automation solution is the Delta/Parallel Link robot. With multiple arms connected to a single base, delta robotic solutions are commonly used in pick-and-place systems, especially when enhanced speed and throughput is crucial.

Improved Safety with Robotic Solutions

One of the main reasons customers come to Precision Automation® is because they are looking for equipment that will protect their employees. Robotic systems provide a solution for exposure to sharp or heavy products, as well as for poor ergonomic situations that may lead to hefty healthcare-related costs for your business.

Furthermore, Precision Automation® protects your products as well as your employees. Because our robotic systems employ specialized sensors, these machines are able to precisely handle delicate products. Their picking and placing process is meticulous, and accurate & consistent packaging ensures items are protected throughout each step of the operation.

Invest in Robotic Solutions Today!

Precision Automation® produces only the highest quality robotic solutions, ensuring our systems are a worry-free investment for customers. Because no two projects are completely identical, our team is adept at collaborating with customers to determine the exact requirements for each robotic system. Our products are built to fit seamlessly into your production or packaging environment, so if you are looking for a simple way to drastically optimize your company, we encourage you to contact a member of our robotic solutions team today!