Complete Production & Processing Line Integration Services

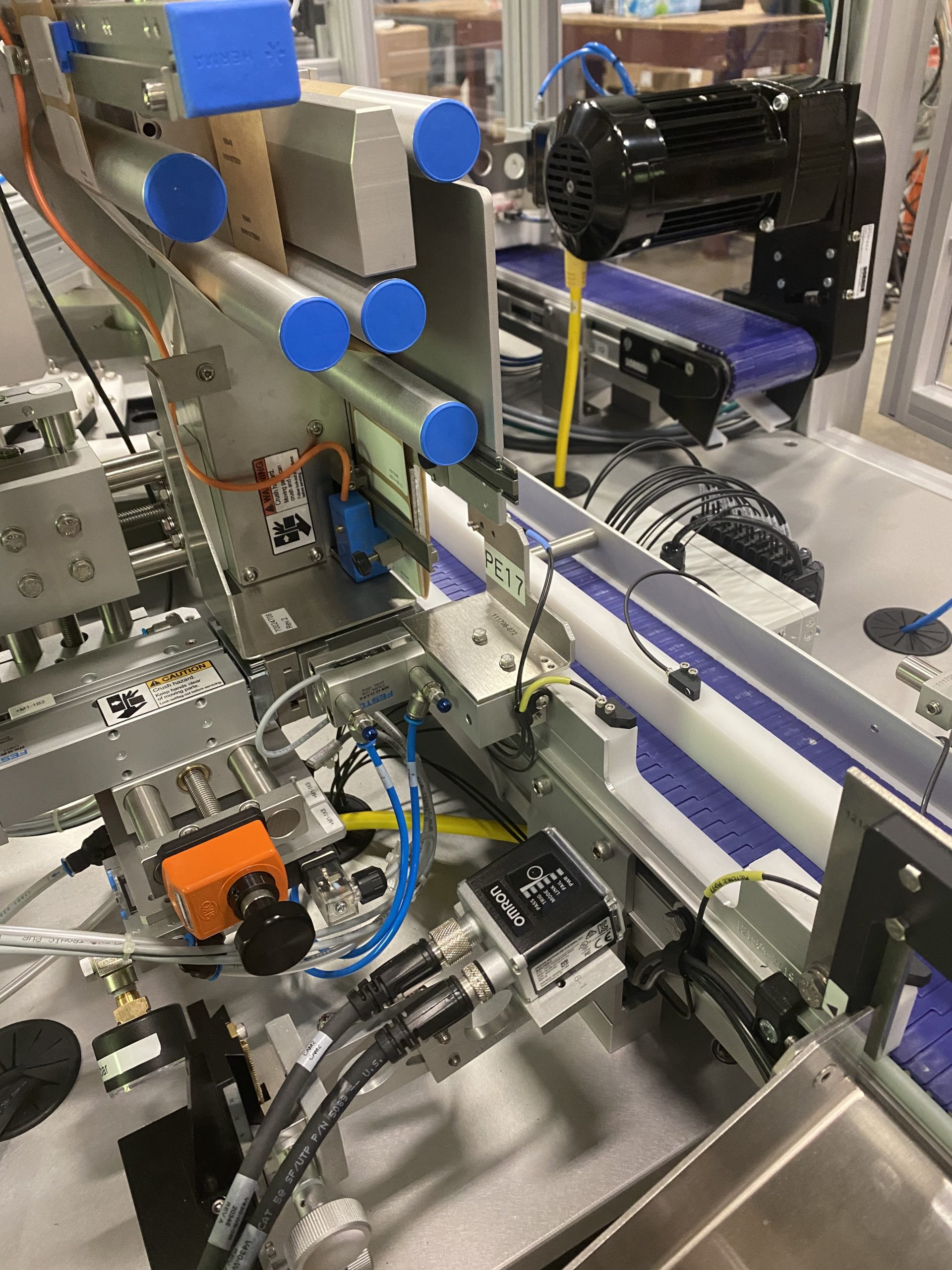

We recently discussed how machine building is a valuable service for Precision Automation’s customers. Another beneficial service our business offers is production & processing line integration. With a diverse offering of automation solutions, our team of sales engineers first determines our client’s primary production issue or slowdown, and plans the project accordingly, be it: robotic, conveyance, labeling, filling, capping, packaging, or all of the above. From initial design of an optimal line layout, to purchasing efficient pieces of equipment, to integration and installation of each system, our team is dedicated to serving each of our customers’ unique needs.

Line Integration Services for Companies with Multiple Locations

The integration services we offer serve our customers’ needs, regardless if they pertain to a single production line or multiple facilities, with each containing a series of connected systems. Larger companies, in particular, benefit from Precision Automation’s in-house engineering capabilities, as these customers use our conveyor systems and filling, capping, and labeling machinery to streamline their business across multiple locations and plants. Our organization not only creates a custom production line integration plan for each location, but we go above and beyond to ensure all the needs of our clients are met. Typically, this includes site visits from sales engineers and/or service technicians who personally travel to our customers’ various plant locations to determine the initial requirements for each new line, as well as installation and implementation.

Line Integration Services for Startups

While our comprehensive production and processing line integration services are ideal for larger companies, that doesn’t mean that developing companies cannot also benefit from our expertise. Precision Automation® has a long history of working with startups, and always strives to continue our partnerships as these companies grow and expand their production and processing capabilities. When first starting out, young companies require a degree of flexibility, and our company answers with the unique ability to provide turnkey production line integration services.

Our Comprehensive Process for Line Integration

As mentioned above, the Precision Automation® team aims to always be available to meet with our customers in-person at their facilities in order to determine the best strategies for production line integration. This site survey is only the initial step of our process to first learn about the operation and facility capacity of our clients.

By constantly collaborating with our customers, Precision Automation® verifies that each new line is outfitted with technology that is compatible with any existing software and databases. This step is vital, as it ensures that the final product of our line integration services is not only efficient, but easy for operators to use.

The final stage of complete line integration is to fully implement all new systems into our customers’ facilities. During this stage, our team is available for production support and will provide maintenance manuals that supply the operators with a useful guide on how to properly manage each line through any faults. At the end of the day, Precision Automation® seeks to optimize the efficiency of our customers’ facilities, which is why we continue to be readily available for customer support even after any integration project has been completed.

Long History of Quality Integration Services

While it was not one of the core service offerings when our company was founded over 75 years ago, Precision Automation® has prided ourselves on adding capabilities and providing efficient integration services for our customers. For example, our company recently designed and integrated unique solutions for a longtime customer in the pharmaceutical industry. This customer relationship, initiated via a series of integration projects, has led to continued machine building and contract manufacturing business opportunities. Our team at Precision Automation® has continued to prioritize high-quality line integration, allowing our customers to reap the benefits of increased productivity, reduced operating costs, improved ergonomics, among many other benefits!