Labeling and Traceability to Improve Supply Chain

Global supply chain logistics and e-commerce continue on through the toughest of times as well as through the strongest of times. Companies that provide consumer packaged goods (CPGs) are more connected than ever, and face the need to maximize their own product and data management so they can satisfy their customers in a timely manner. One of the most efficient ways to accomplish this is through barcode labeling and product traceability.

A recent article in Packaging Strategies magazine focused on companies using labeling in order to improve traceability within their operations. Citing the need to be able to “track a product throughout its lifecycle”, companies are trending toward using labels to “record relevant data along the way.” Essentially, each label is linking all of the specific product information back to the source, allowing the company to effectively track the product and all relevant information, which saves time and mitigates risk.

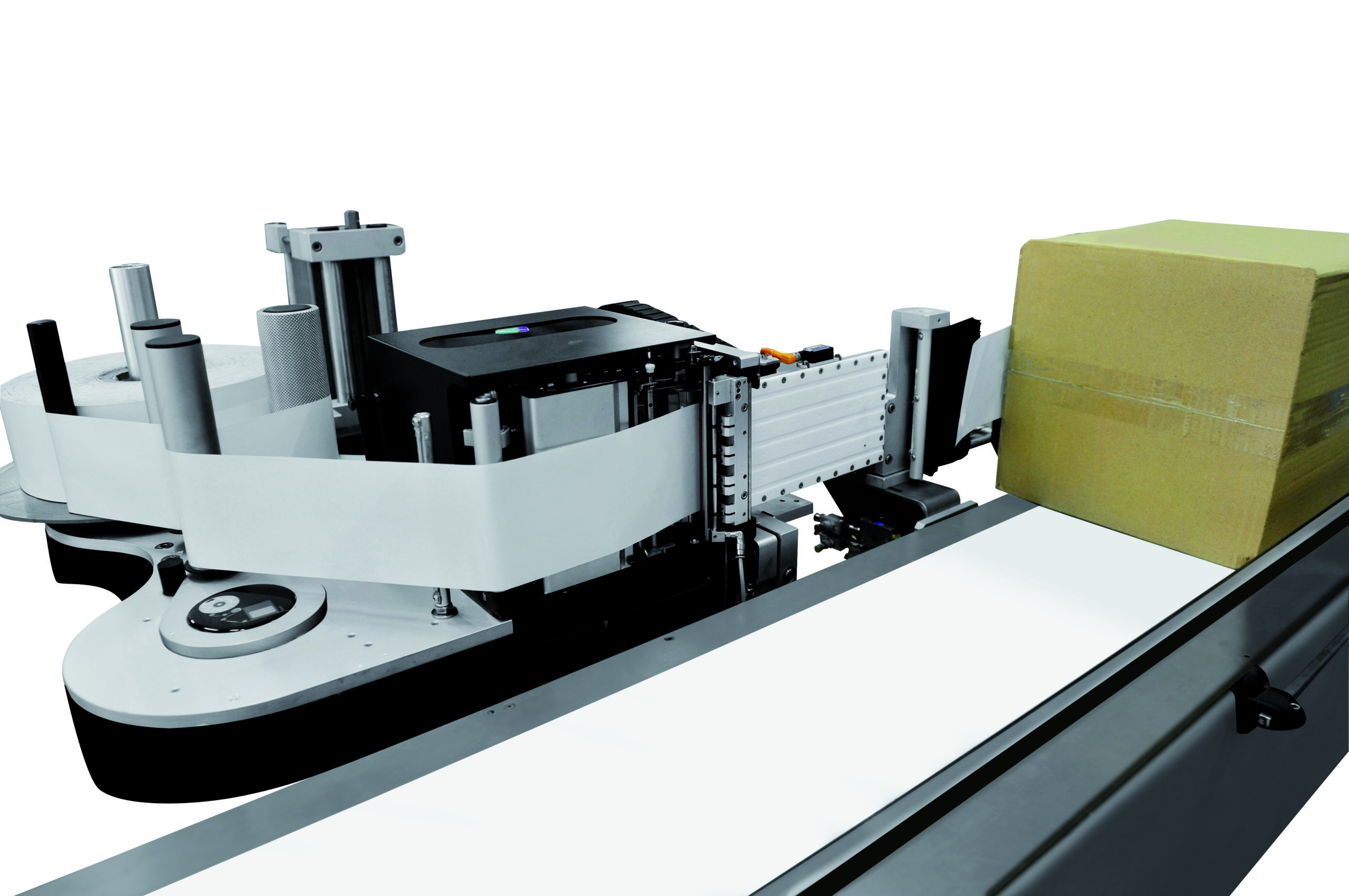

Complex supply chain dynamics call for solutions that can solve them; Precision Automation solutions answer that call with speed, versatility, and robustness. The sales engineers who design and integrate the labeling and scanning systems tailor them to each customer’s specific requirements, and routinely handle projects of varying intricacy. From print-and-apply to simple labeling, our systems are turnkey and involve as many process stages as our customer prefers.

A new method of print & apply that we are featuring is Print-On-Demand labeling, which utilizes full color printing to create and apply labels. This solution is ideally used in package/carton labeling applications for users with frequent product changeover. The POD system can be utilized by those who need to change their label after small batch production; for example, companies in niche markets like cannabis/CBD, craft breweries, or chemical manufacturers with varying hazard label requirements. This video shows an example of this system in place at the recent Pack Expo East trade show, from our booth display:

A separate article from Pro Food World magazine discusses how retailers and their CPGs are leaning toward 2D barcodes and RFID, instead of previously used UPCs. The purpose there would be for barcode labels to contain more & more specific data, while still remaining fully readable by barcode scanning systems. Other factors that propel this trend in barcode evolution include the need to minimize counterfeit good production as well as waste prevention (RE: expiration dates).

Ultimately, traceability is vital to upgrading barcodes and internal systems, and labeling is the key. By scanning a barcode, vast amounts of information is uploaded and transferred, and companies can manage their inventory properly. Contact Us at any time and consult with one of our sales engineers to find out how Precision Automation solutions can best maximize labeling operation in your facility today.