The Components of a Labeling System

We have talked about the latest series of Arca labeling systems as well as the reasoning for investing in automatic labeling, but we have not yet broken down a system into individual assemblies. This blog is intended to explain the different components of a labeling system, and why they are important to the overall effort of the machine itself. Whether you are brand new to the world of labeling solutions or have been using them for decades- hopefully you learn something new today.

There are different types of Arca labeling systems, but each one’s key task is to automatically apply a label to a product or case. At its most fundamental definition, a labeling system is a machine made up of a combination of electrical and mechanical components. The purpose is to produce and apply labels onto products- whether they are individual pieces or a quantity packed into a case.

For the basic components of the labeling system, we will go over each significant assembly item individually:

The Label Roll Housing is a self-descriptive name for where the roll of labels rests while it is being unwound to dispense the labels. The new, full roll is manually placed onto the housing and after all the labels are dispensed, the control unit alerts the operator that it needs to be reloaded.

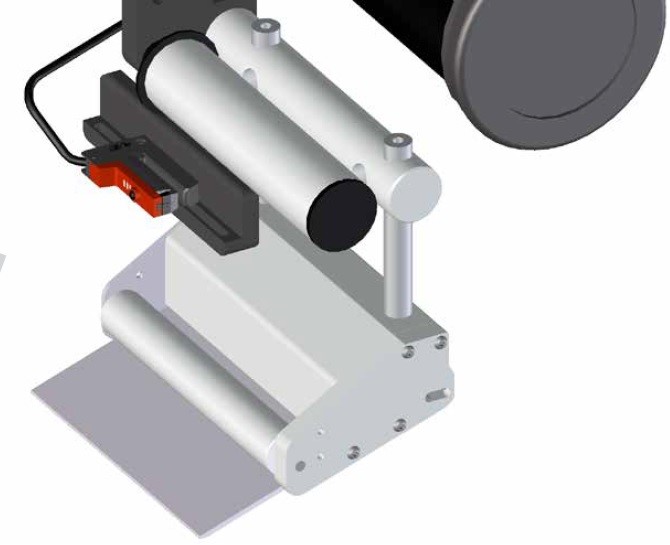

The Unwind is an assembly of parts that unwinds the roll of labels in order to dispense each one when the product sensor is triggered. After the label is dispensed, the Unwind maintains tension, keeping the web positioned properly between label cycles.

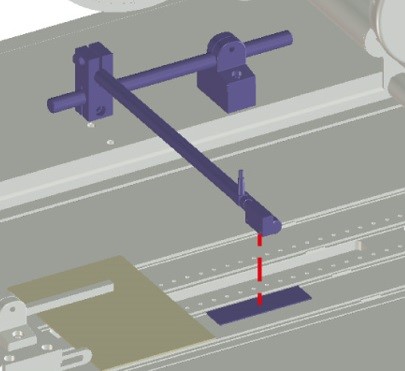

The Peeler is the part of the labeler positioned closest to the product or case, and it separates the label from the liner for accurate and efficient placement. Instead of a Peeler, a Tamp Pad utilizes vacuum holding the label securely until it is triggered to apply the label.

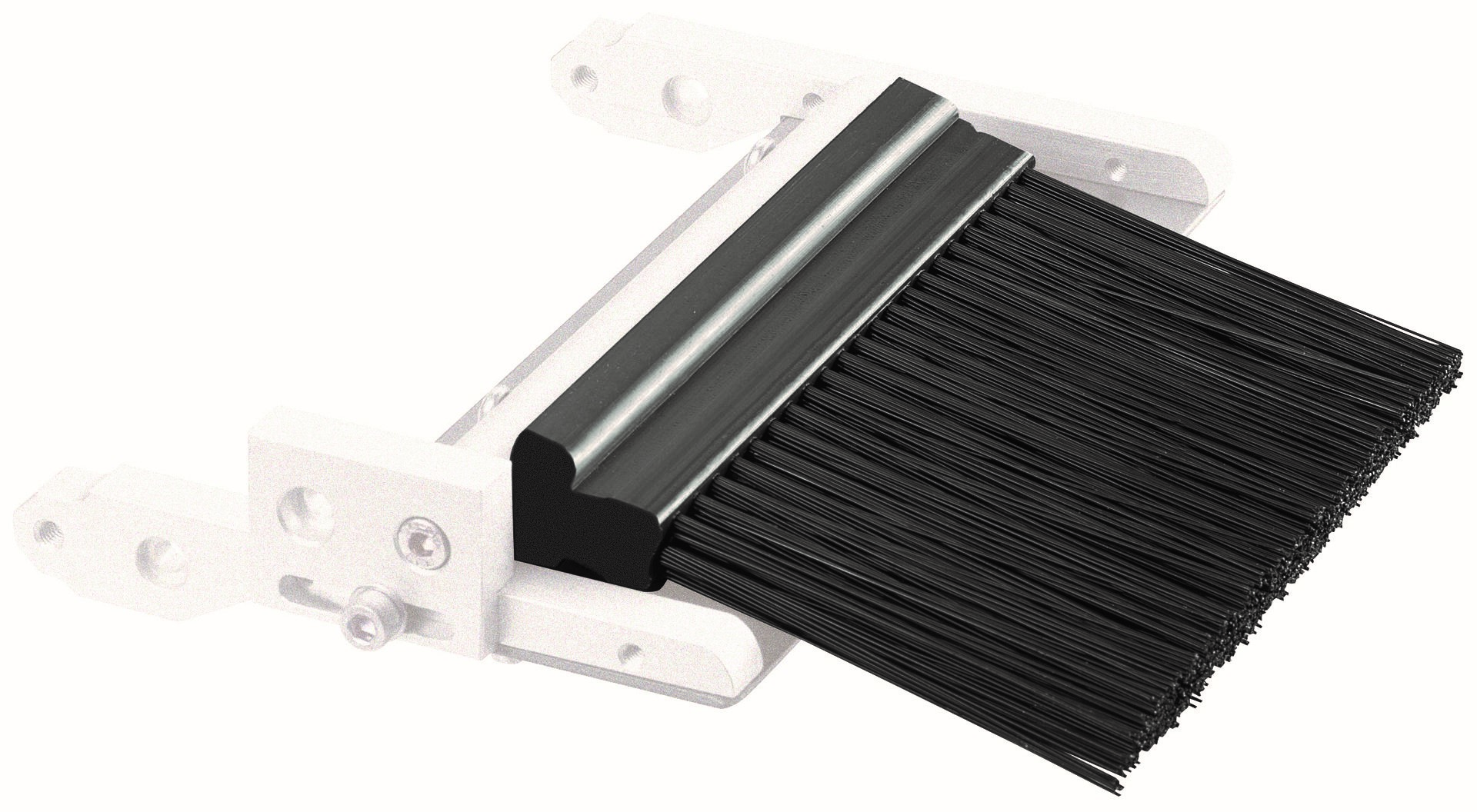

The Adapter- usually a brush (as seen above) or an idler roller- applies gentle but necessary pressure to ensure the label is permanently placed onto the product or box.

The Drive Unit utilizes a rubber-coated roller and a smaller contrast roller to work closely with the Unwind to control the speed and drive of the web throughout the labeling cycle.

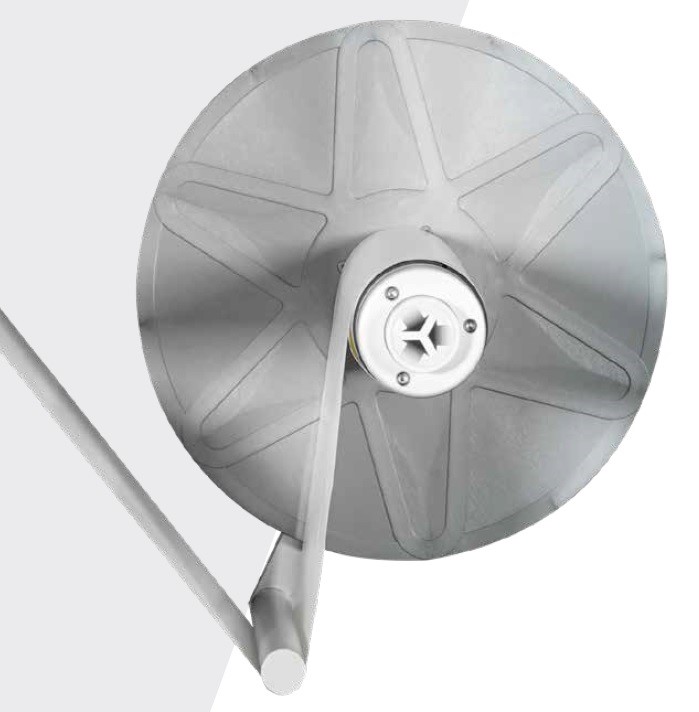

The Rewind is the system that collects up the liner by rewinding it onto a mandrel into an increasingly-growing roll as the system operates.

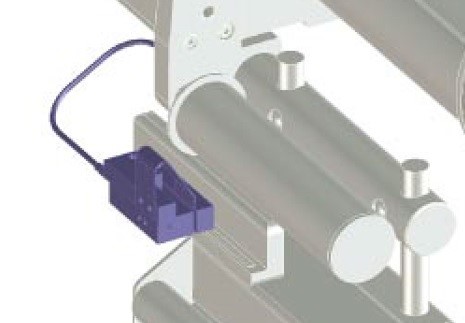

The Product Detection is typically a photo-eye sensor but can be another type of switch. Once a product or case is identified, an output signal is sent to the labeler initiating the label cycle.

Similar to the Product Detection, the Label Sensor reads the gaps between the labels and controls the stop/start and the dispensing. The Label Sensor can be a photo-eye or a mechanical sensor (which is typically used for clear labels).

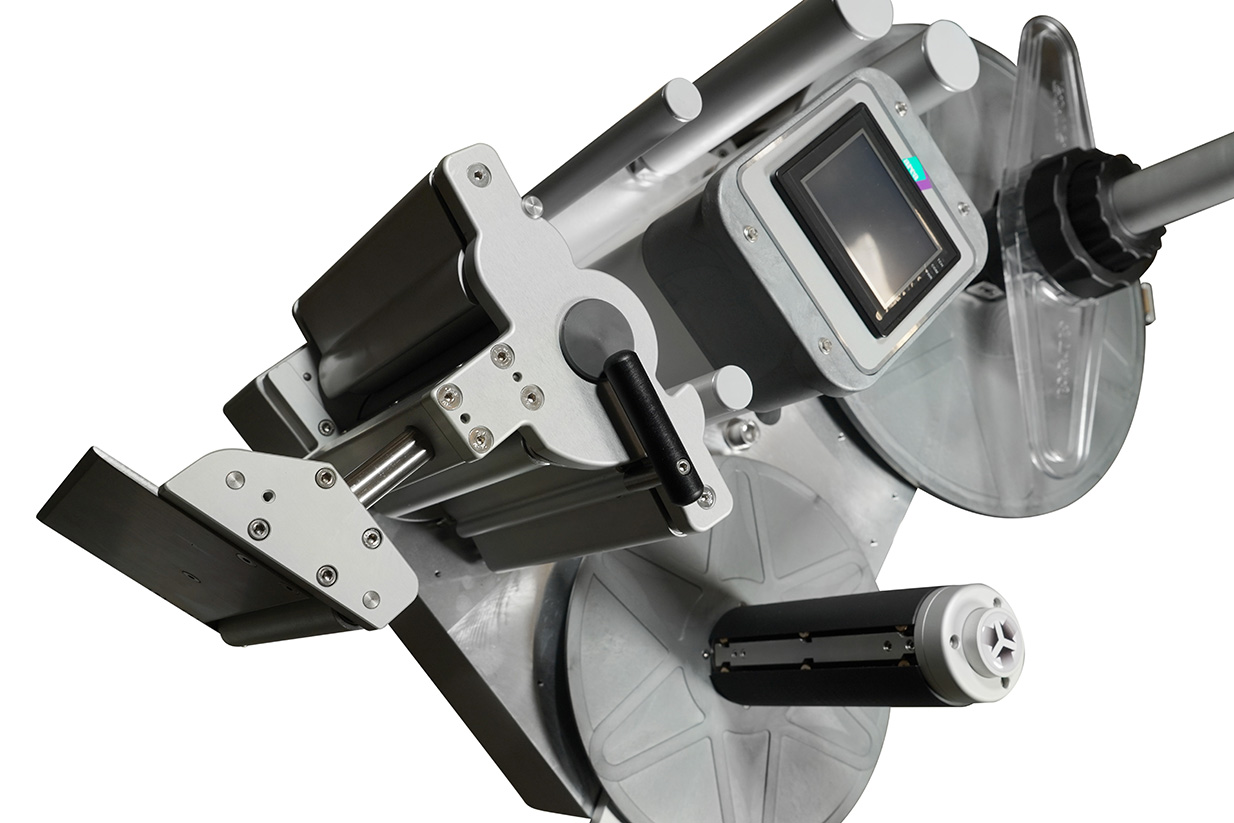

The Control Unit is the brains and interface of the system. It is used to set & configure the parameters of the labeler. The touchscreen display provides the status and conditions of the labeler for the operator to monitor.

As with any automation system, more goes into this labeler than just the components mentioned above. However, these are the primary pieces that make a machine like this run effectively to guarantee consistent proper placement of labels. When a customer purchases a labeling system, our team also supplies a recommended spare parts list. Many of the key items from that list are found within the assemblies above because they are crucial to the system’s operation.

If you would like to learn more about the different types of labeling systems and how they might fit within your respective operation, please contact us today. Our team aims to have a conversation to first learn about the space involved, the products to be labeled, the targeted rate, and some other pertinent details. After investigating some sample products, cases, or labels, we can provide a quotation for the right labeling solution that would best complement your business needs & goals.